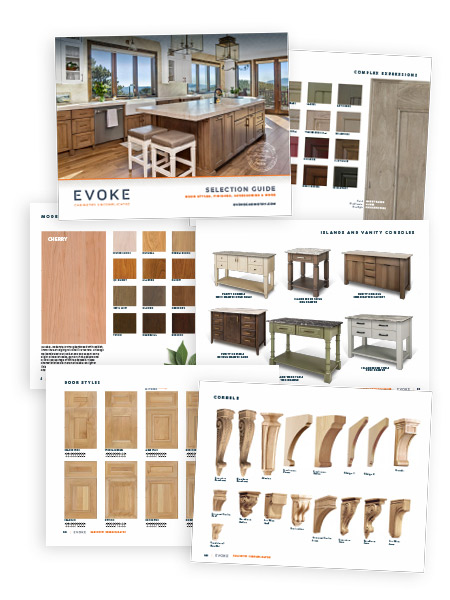

LEARN MORE ABOUT EVOKE

Explore the world of handcrafted furniture grade cabinetry that is tailored to fit you and your style.

Simply download a brochure or request information about a qualified dealer near you.

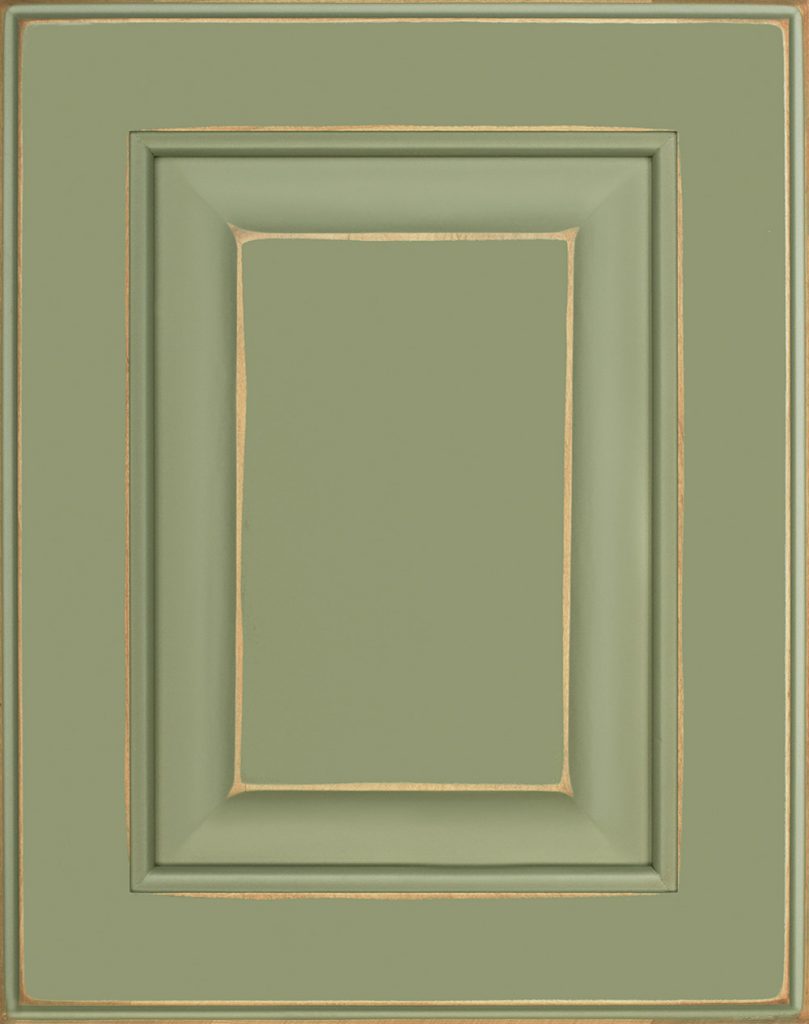

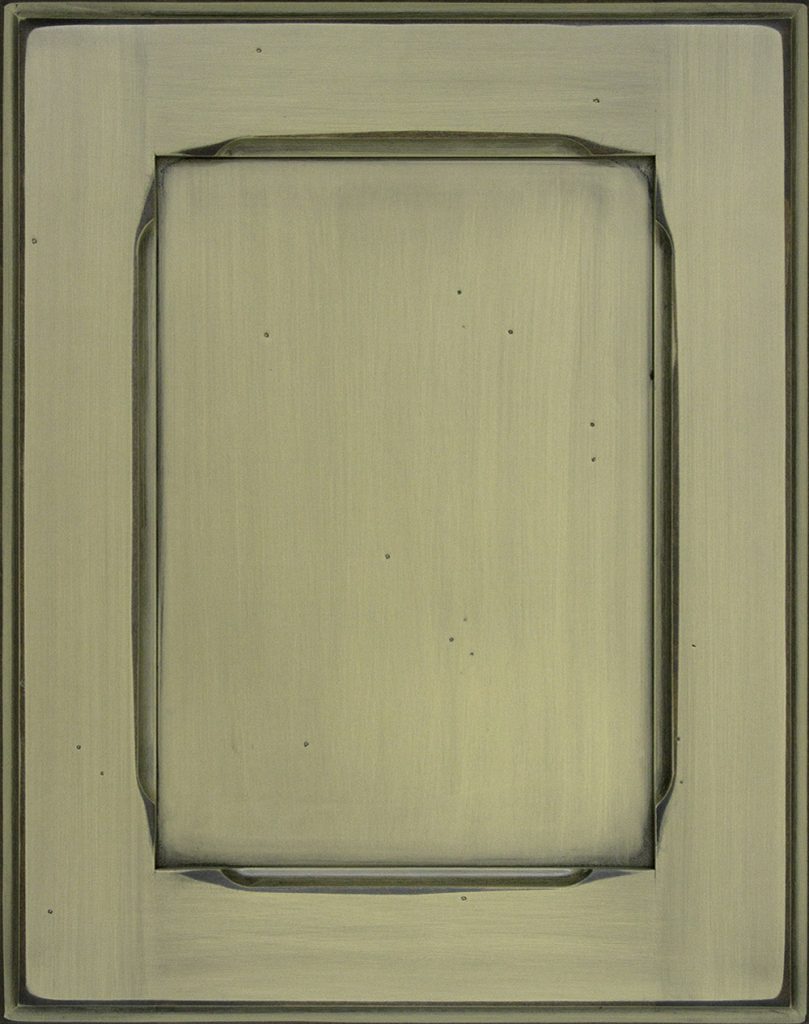

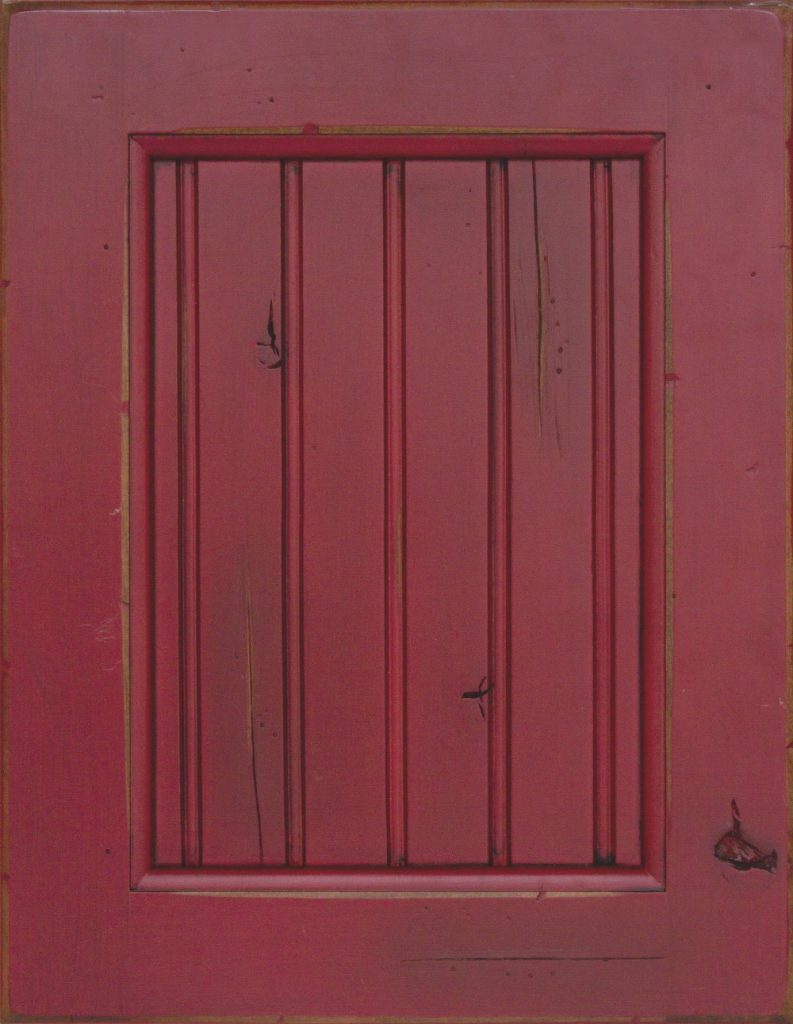

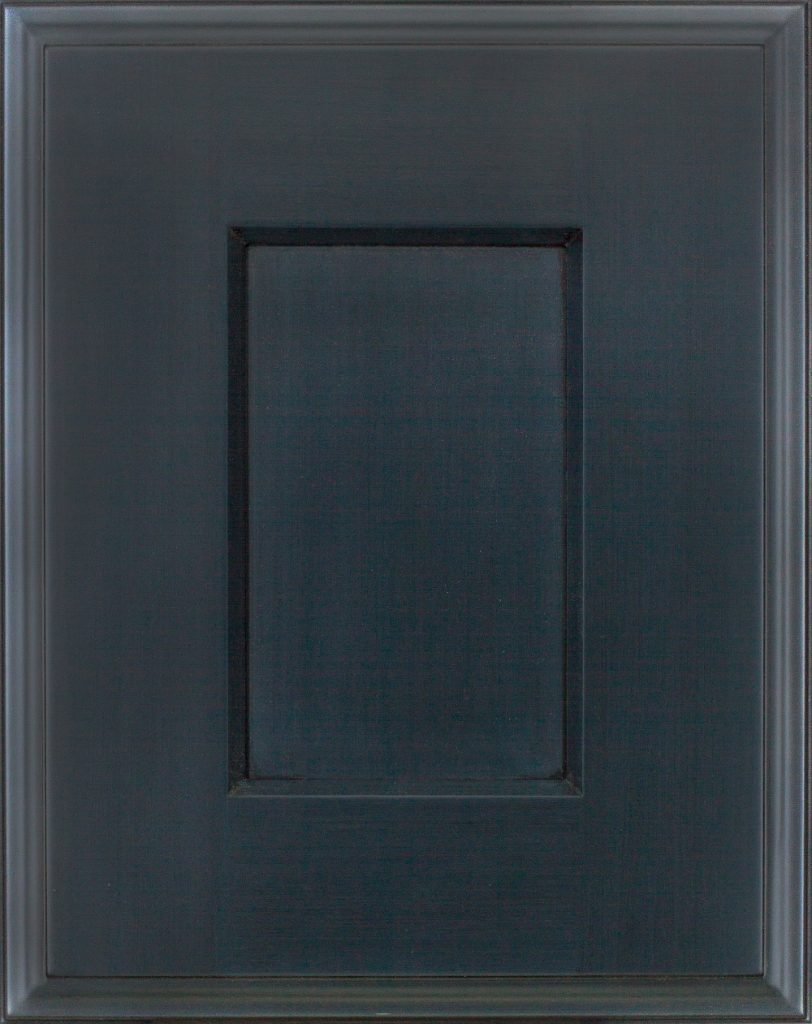

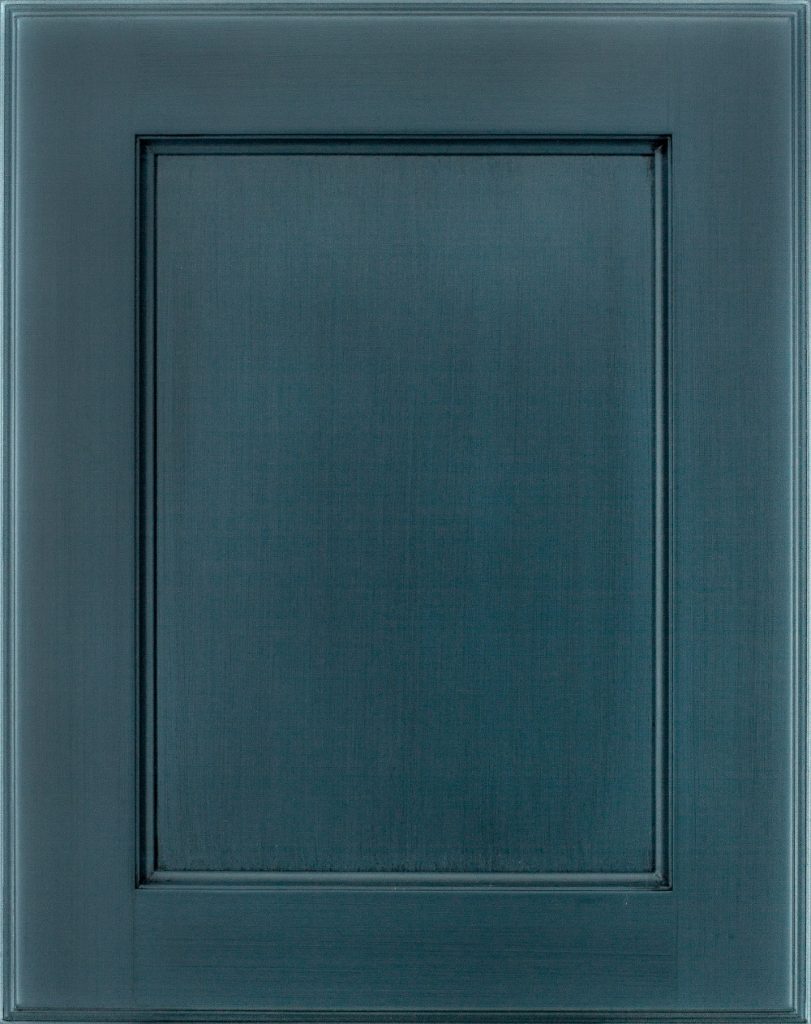

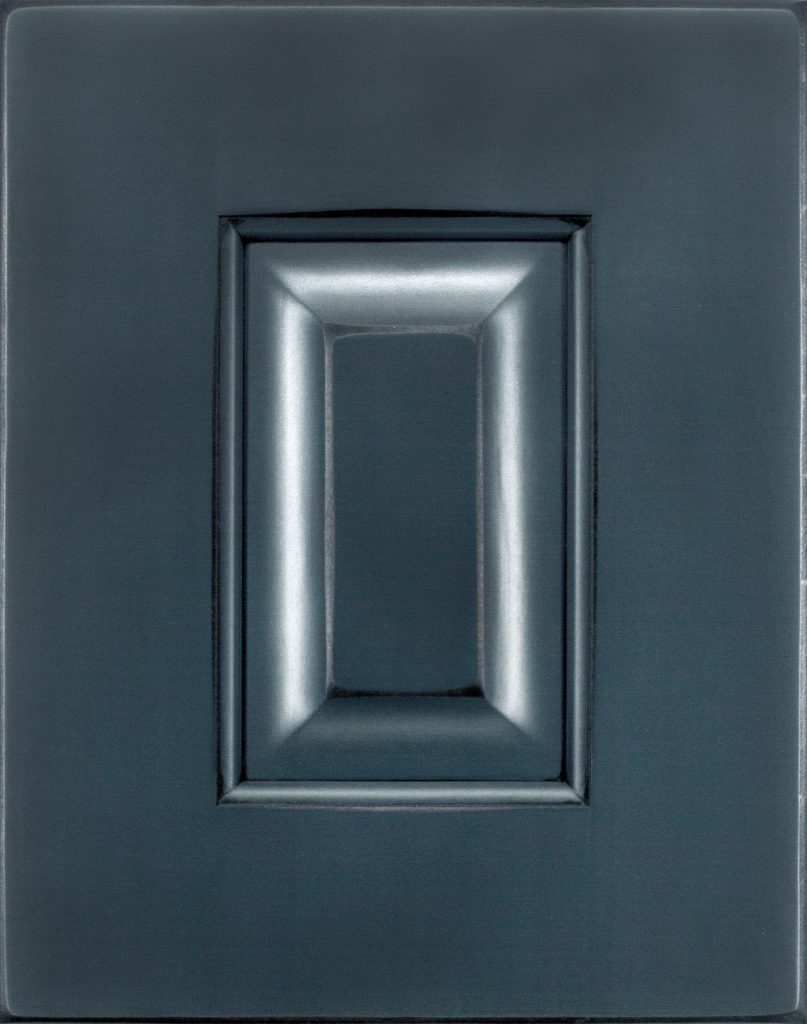

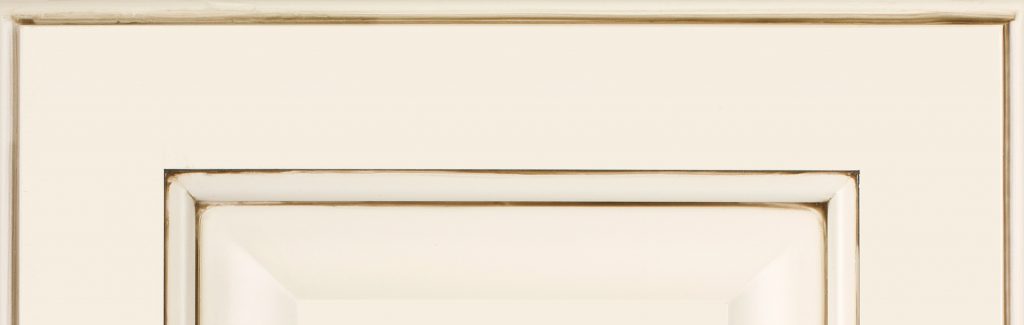

Paint glazes are a type of coating that can work wonders in enhancing the appearance of your cabinets. One of the unique features of paint glazes is that they are translucent or semi-transparent, which makes them a great tool for creating a soft, dimensional effect by allowing the base color to shine through. They are applied over a basecoat of paint to create a layer that adds depth and richness to the surface. Paint glazes are versatile and have a wide range of applications in the realm of decorative painting. They are perfect for enhancing any paint finishes giving you that unique one of a kind look to last for a long time.

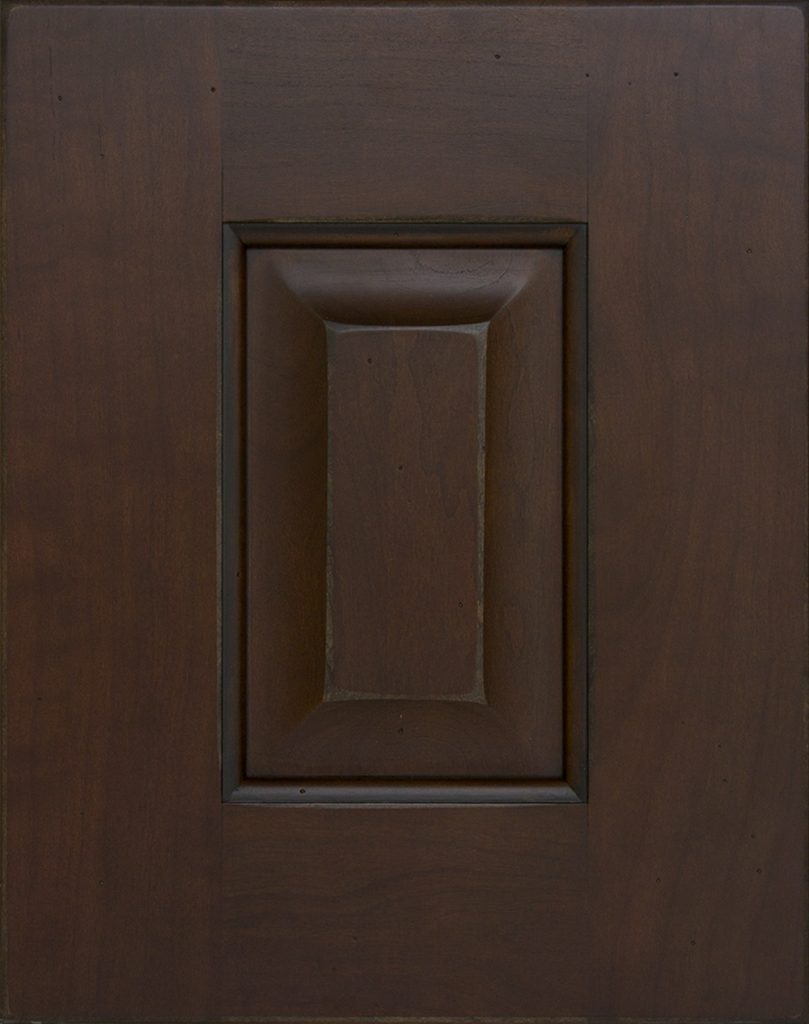

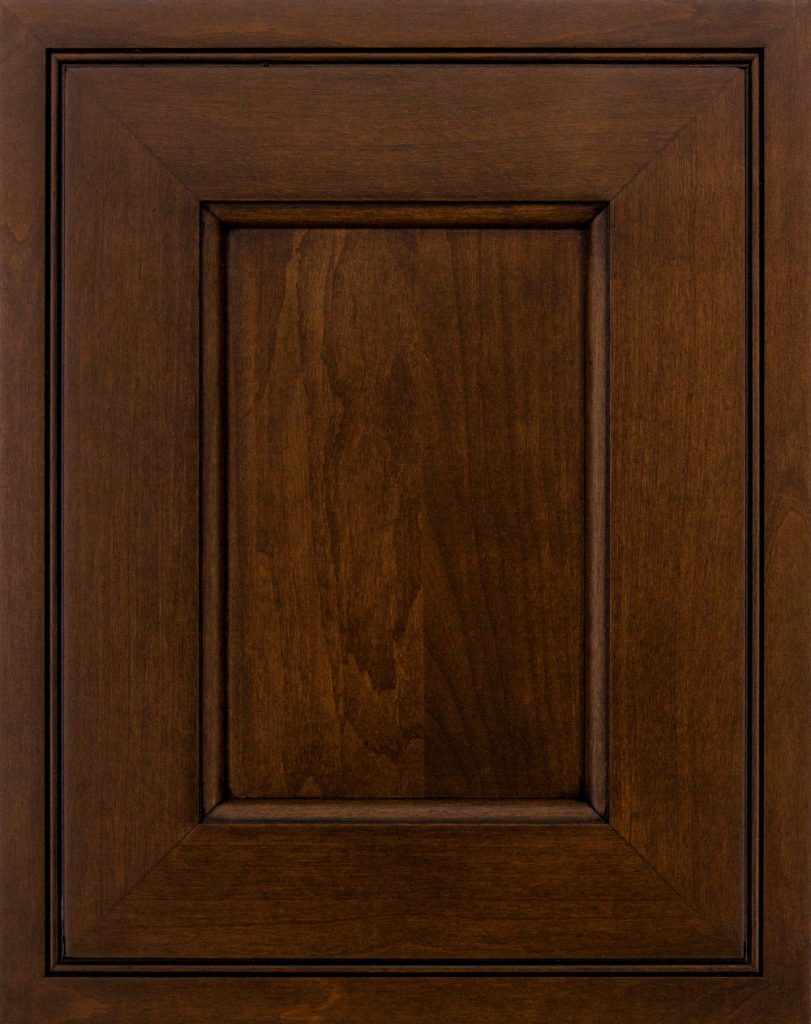

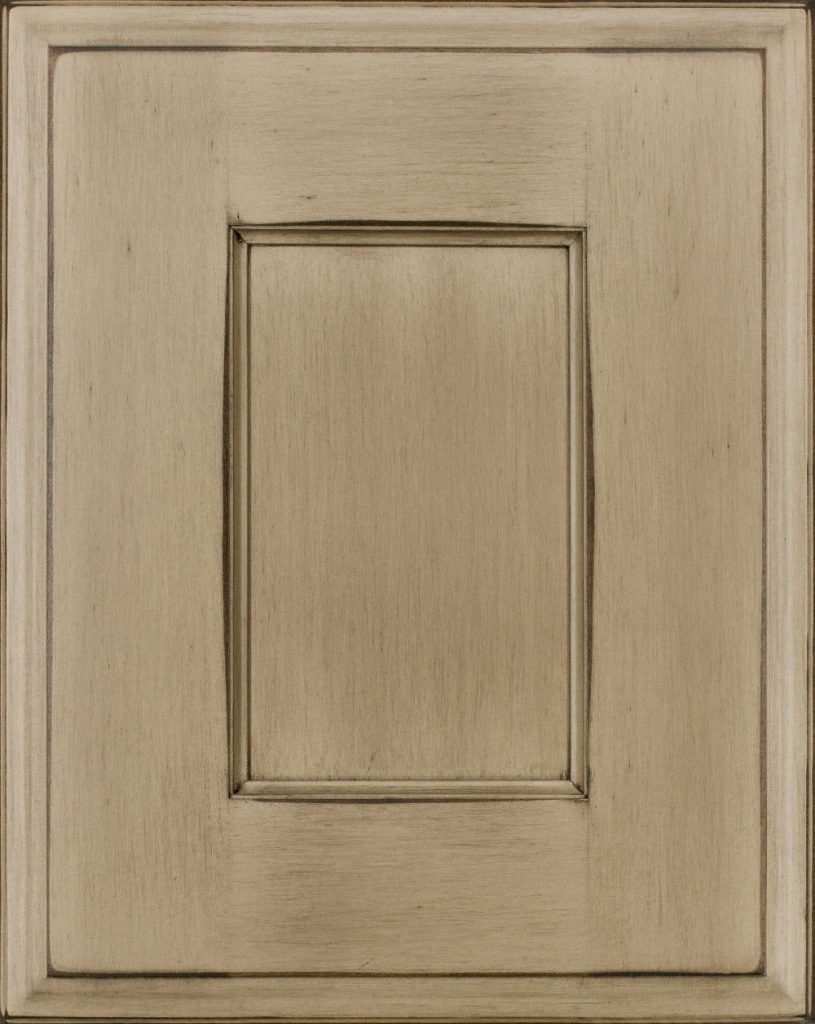

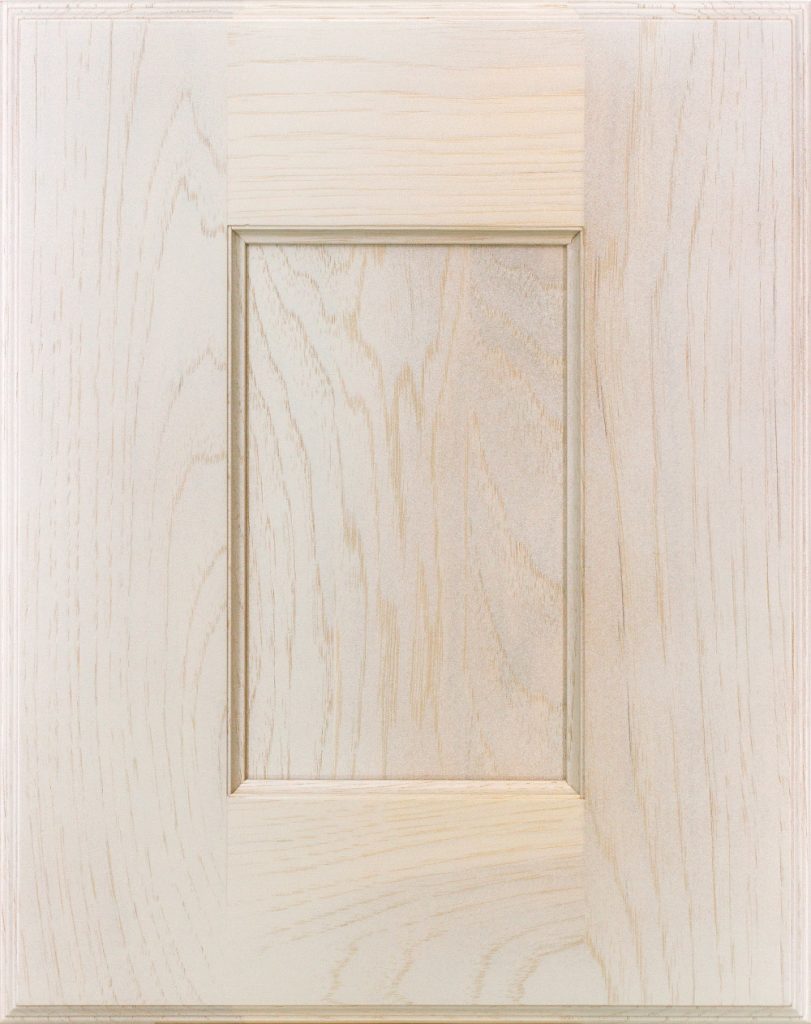

Stain glazes are a versatile way to enhance and preserve the natural beauty of wood surfaces. They work by penetrating the wood’s surface and highlighting the unique textures and patterns found within each piece. This process of highlighting the grain adds depth and richness to the wood’s overall appearance. It is also worth noting that these glazes come in a broad range of hues, from light and subtle tones to richer, darker shades, catering to a variety of tastes and preferences. The result is a timeless and warm appearance that can complement any design aesthetic. Ultimately, this makes stain glazes a go-to option for anyone looking to add warmth and character to their wooden surfaces.

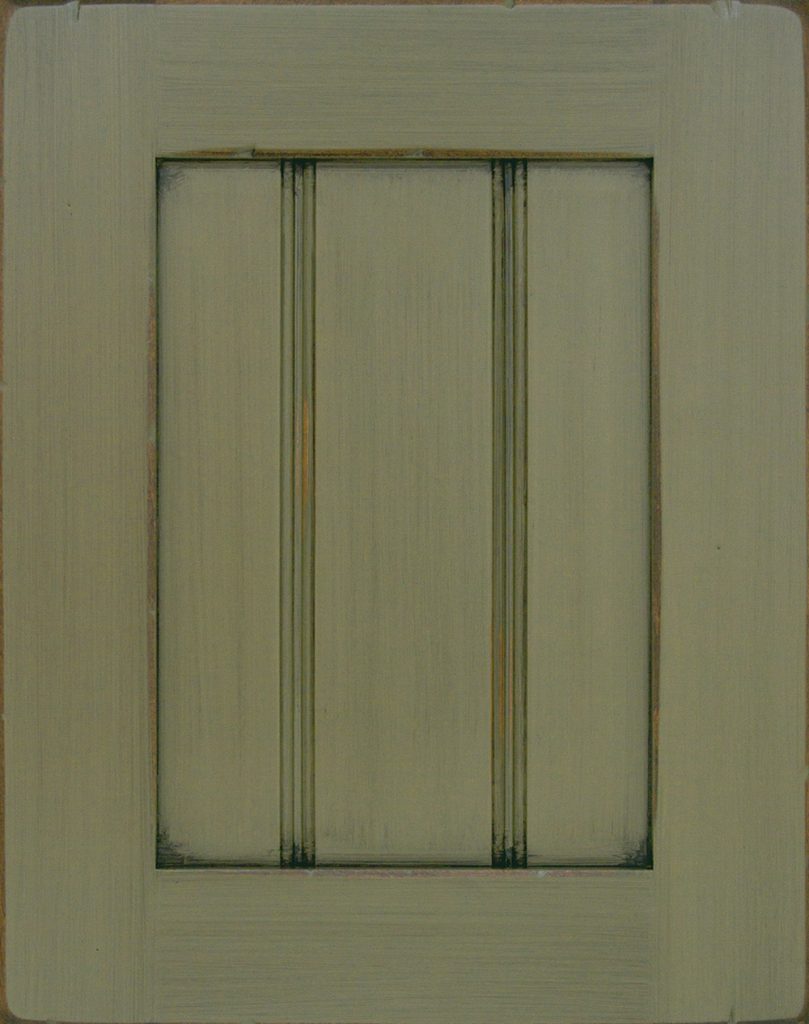

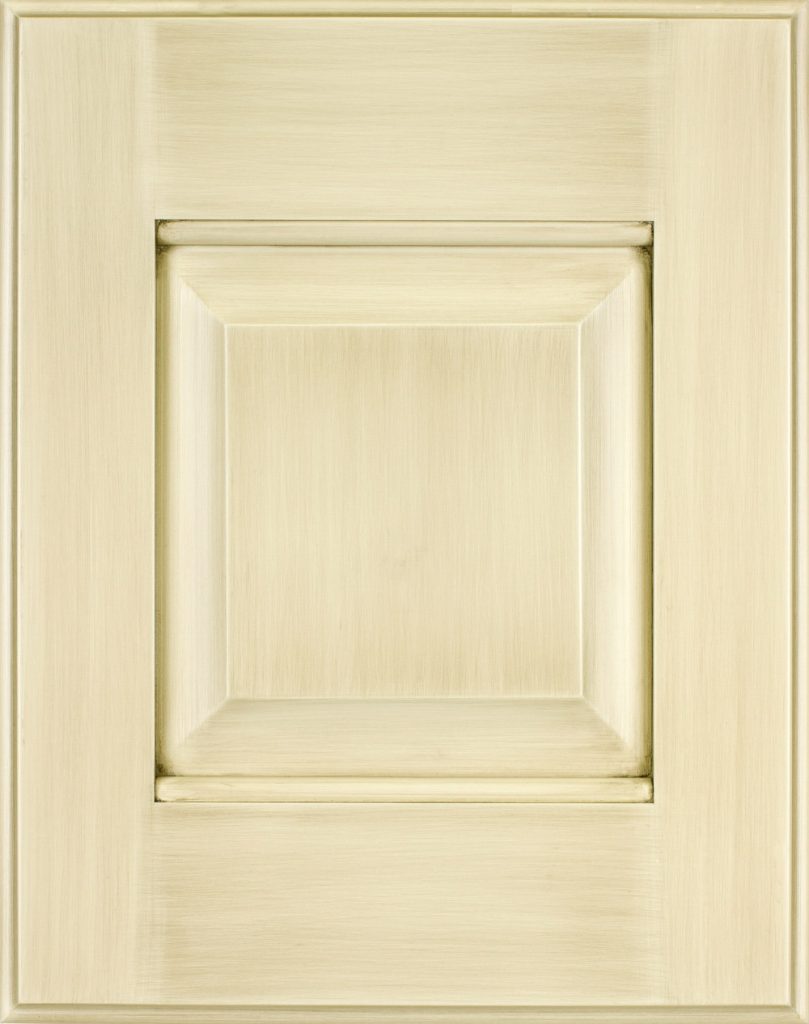

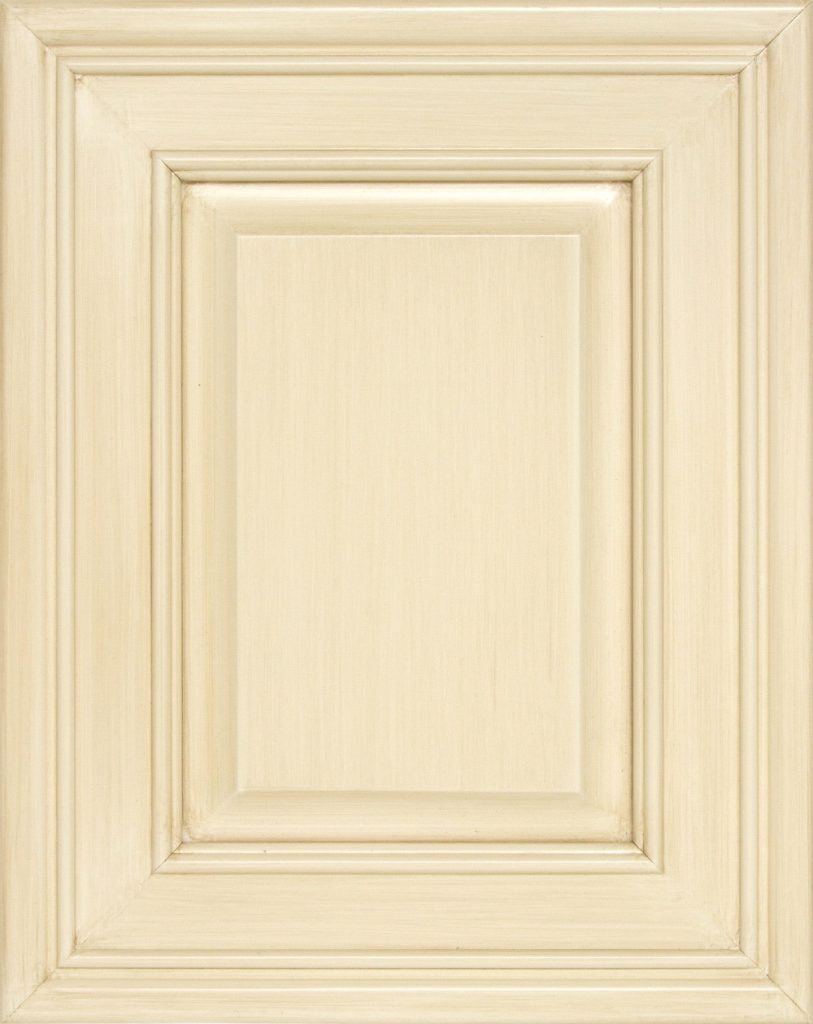

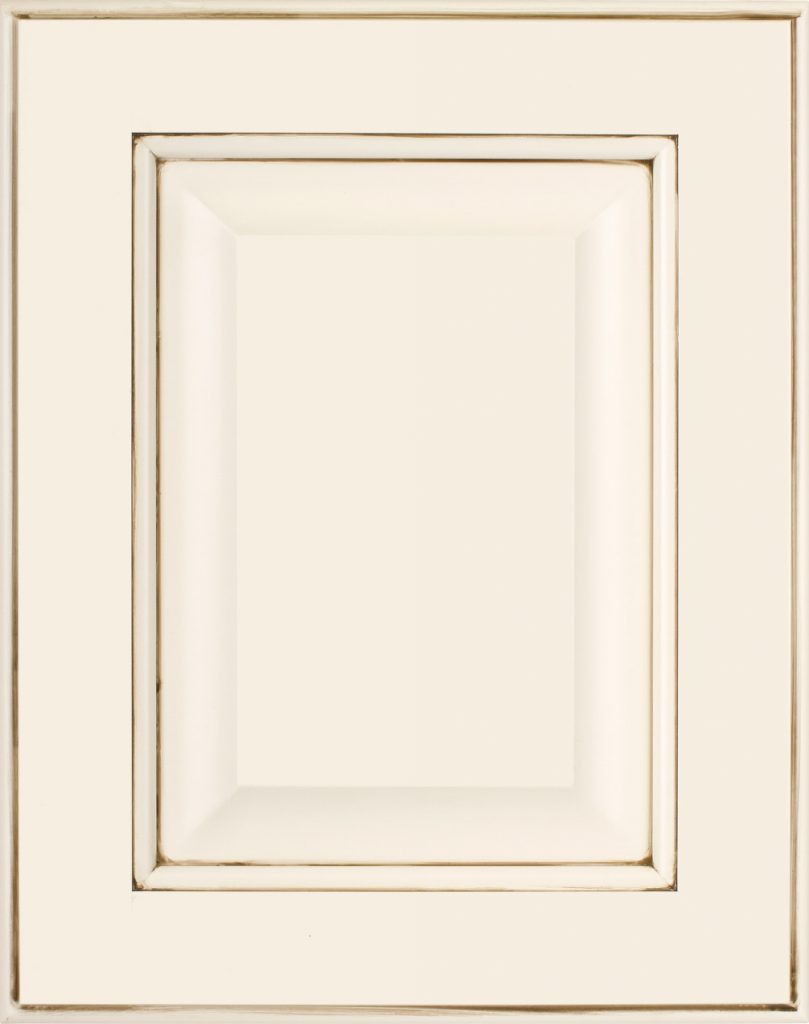

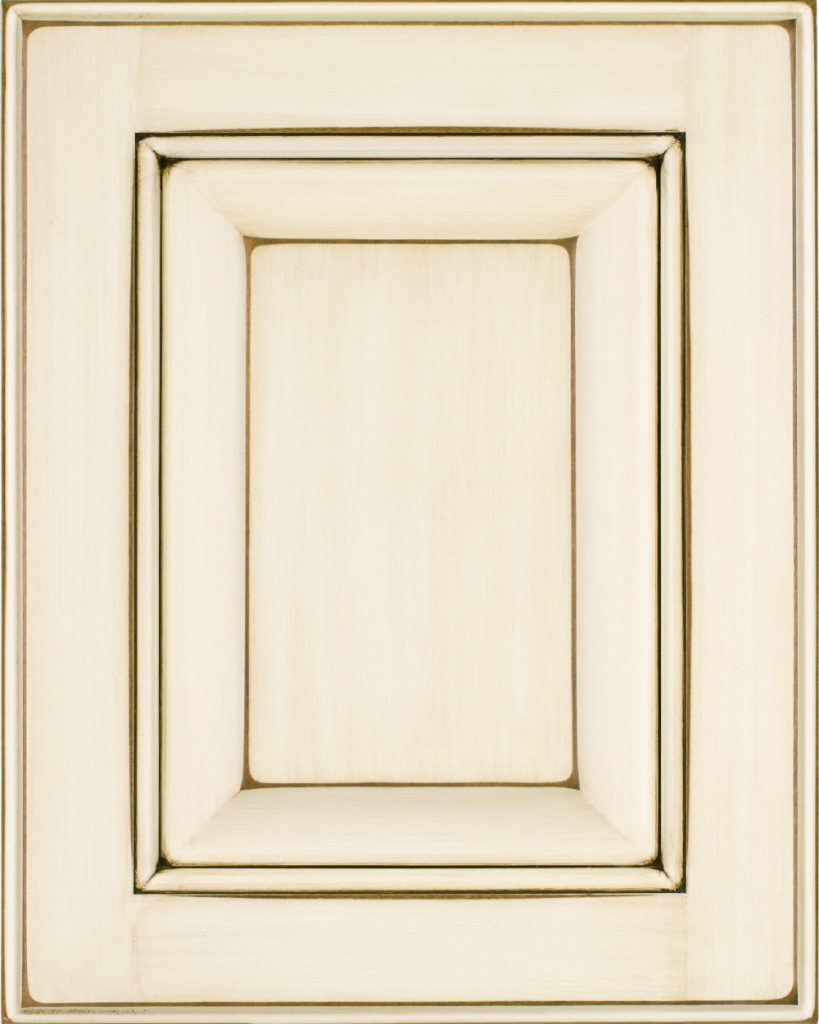

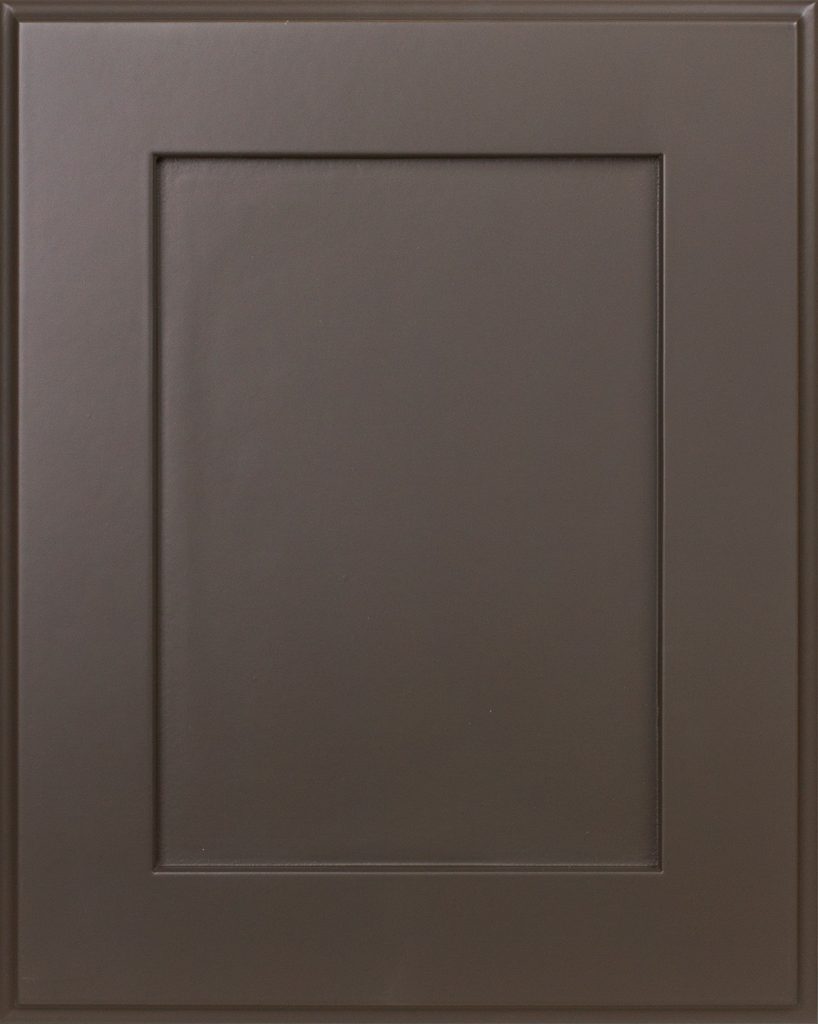

The choice between brushed glaze and wiped glaze depends on the desired aesthetic and the overall style of the cabinets. Brushed glaze offers a more textured and aged look, while wiped glaze provides a smoother and more uniform appearance. Both techniques can enhance the beauty of the cabinets and complement the overall design scheme of the space.

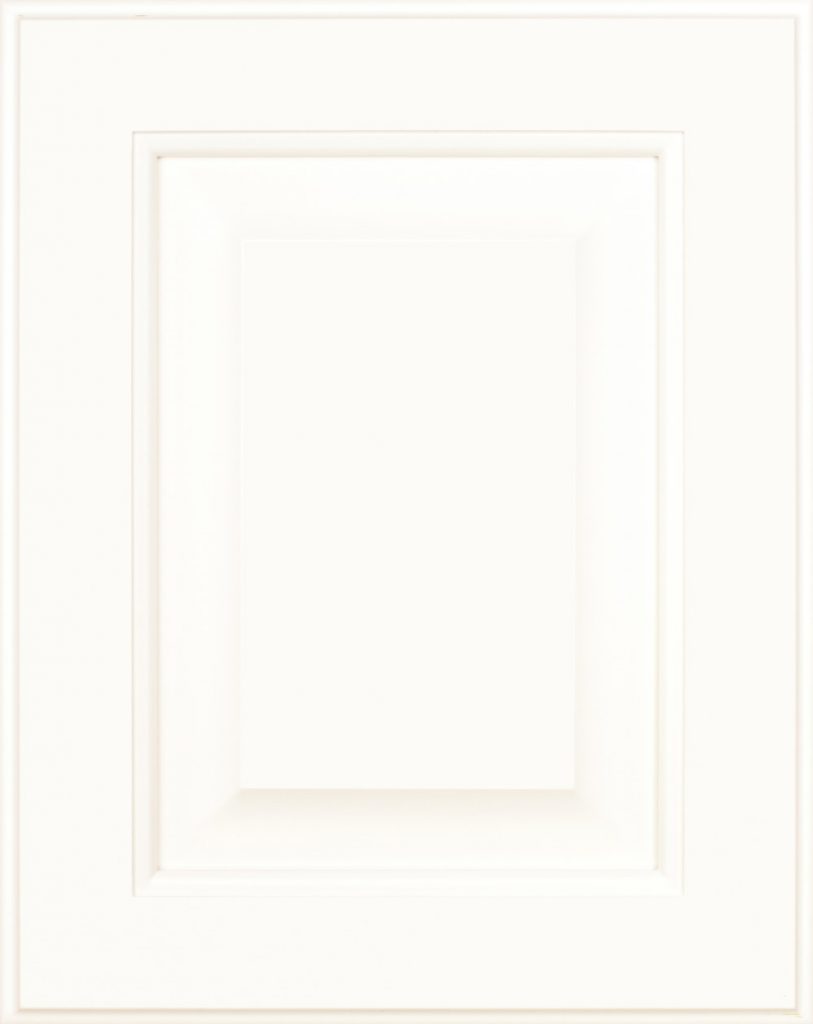

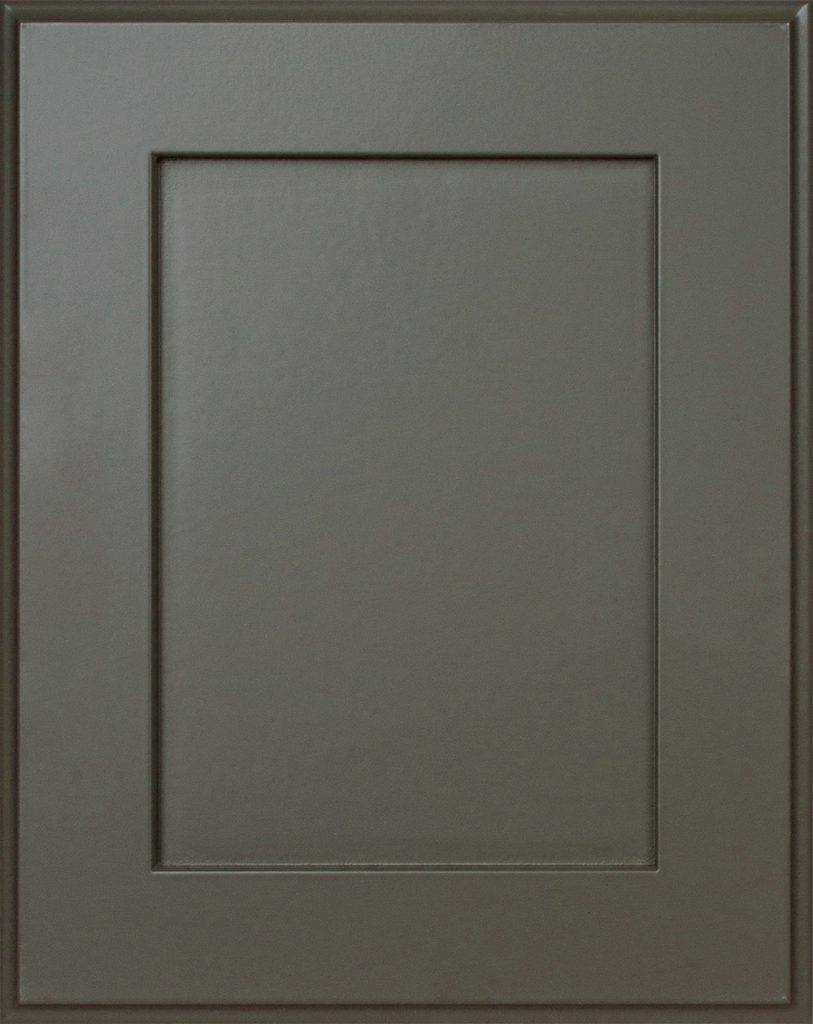

Wiped glaze is a technique that is applied to the cabinet surface using a cloth or sponge and then immediately wiped off. The glaze is spread evenly across the cabinet, and the excess is removed, leaving a subtle and uniform layer of glaze on the surface. Wiped glaze creates a softer and smoother appearance compared to brushed glaze. It adds a hint of color and depth to the cabinets while maintaining a more uniform and refined finish. Wiped glaze is often chosen for a more contemporary or traditional look, depending on the color and technique used.

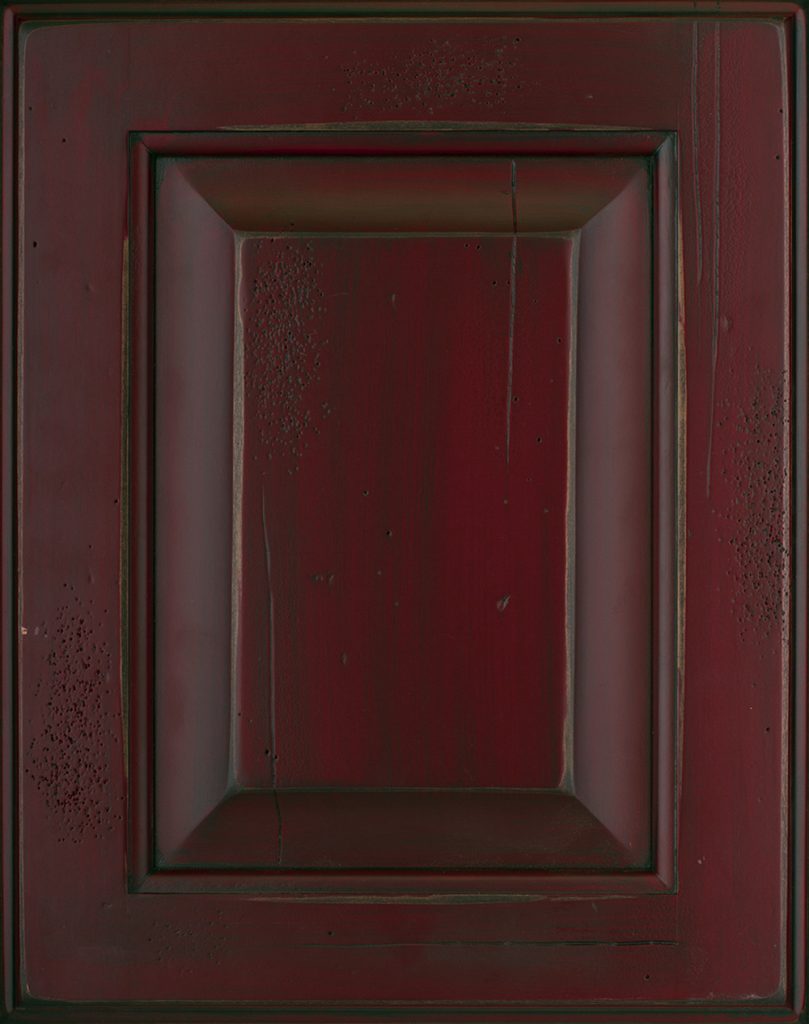

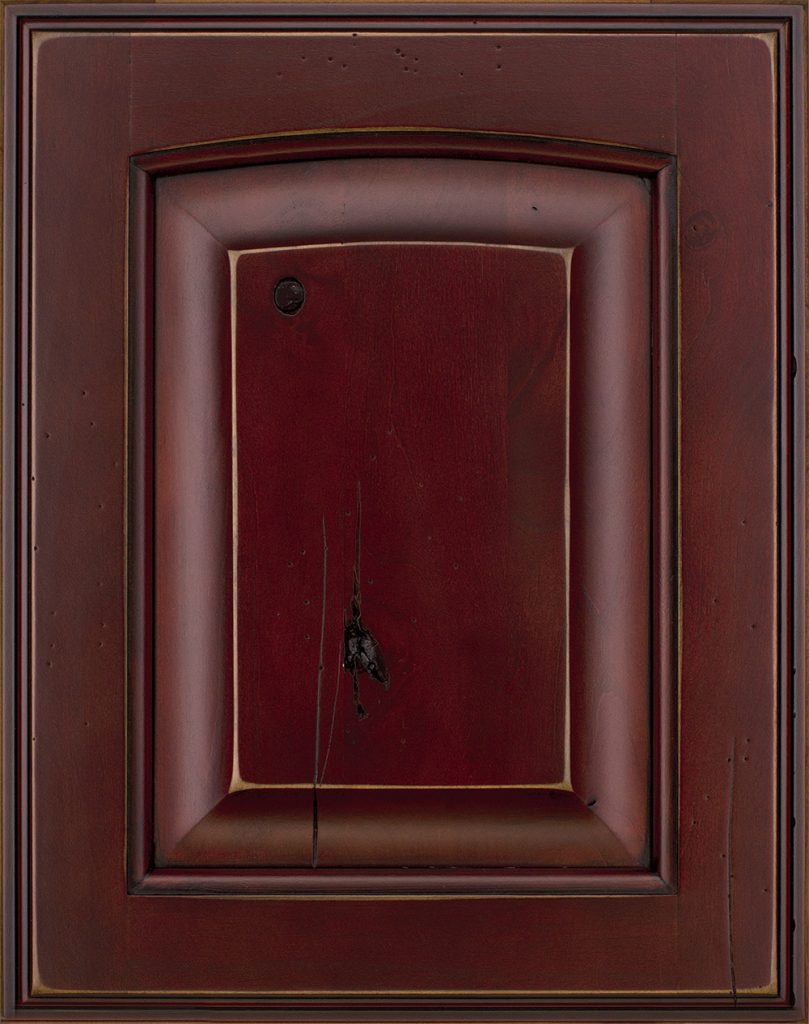

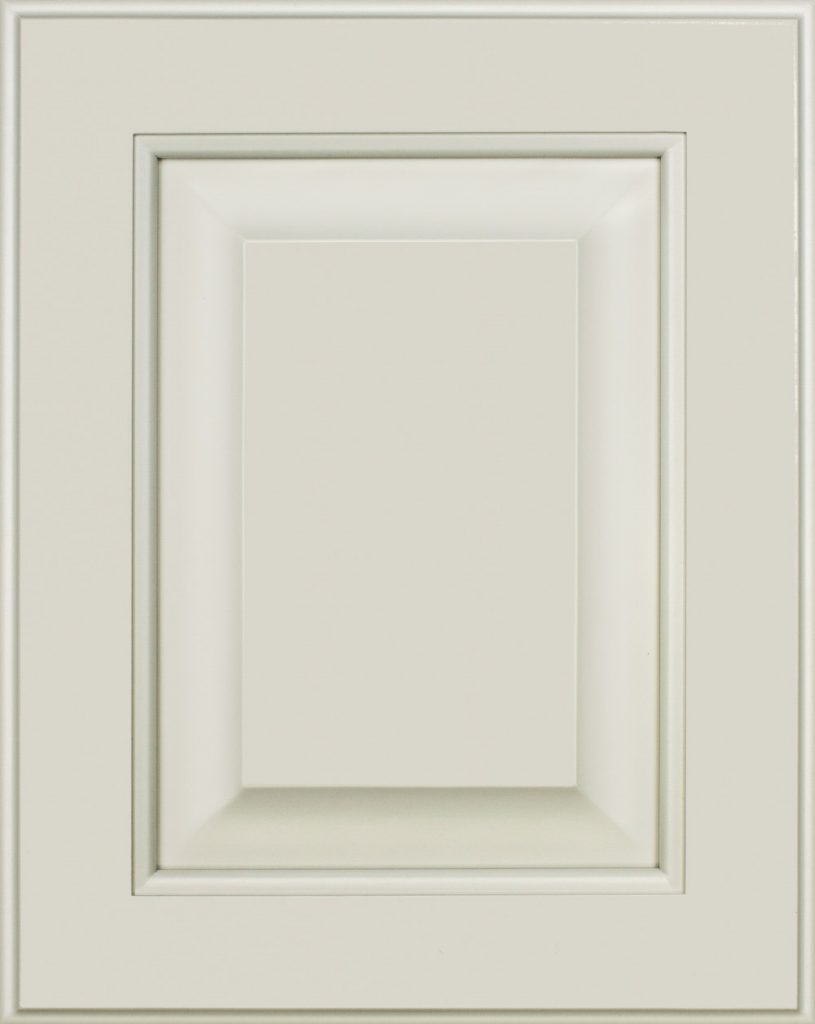

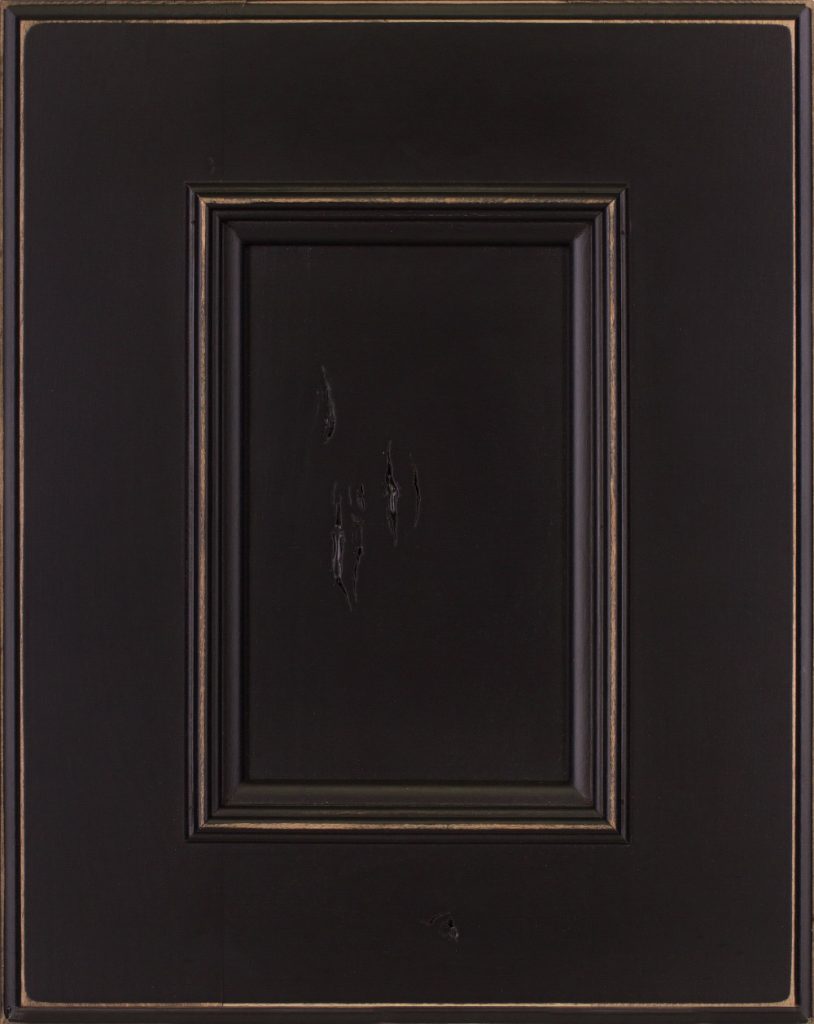

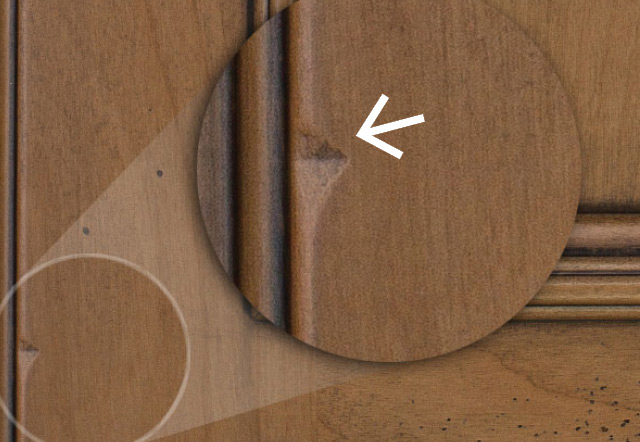

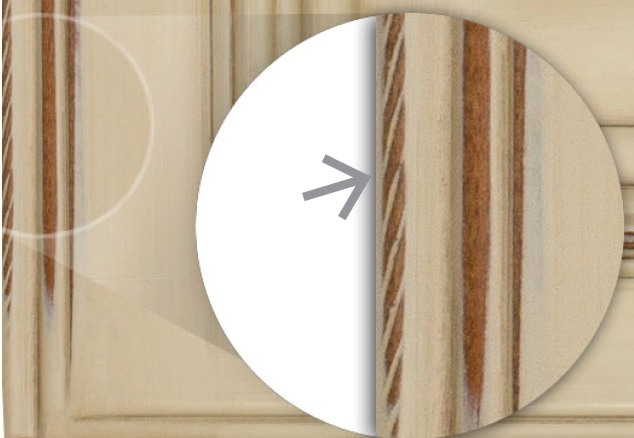

Brushed glaze is a technique involves applying the glaze onto the cabinet surface using a brush. The brush strokes create a textured or brushed appearance, adding depth and dimension to the cabinets. Brushed glaze is often used to achieve a more rustic or aged look. The glaze is typically applied in a controlled manner, allowing it to settle into crevices, corners, and recessed areas, highlighting the details of the cabinet design. Excess glaze may be wiped off the flat surfaces, leaving behind a more concentrated effect in the brushstrokes.

Then (10) types of aging (distressings) techniques are available in a variety of combinations. Aging is a handmade artistic process and, like any fine art, no two pieces will be identical. Not all types of aging techniques are available on all wood species.

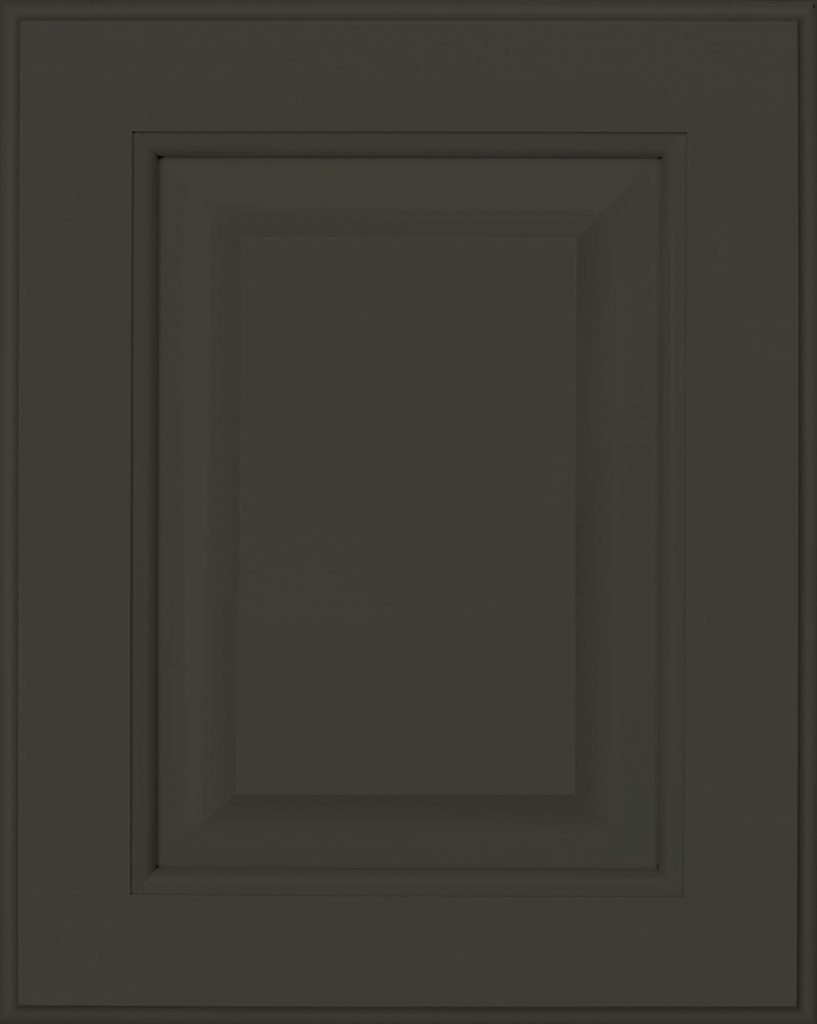

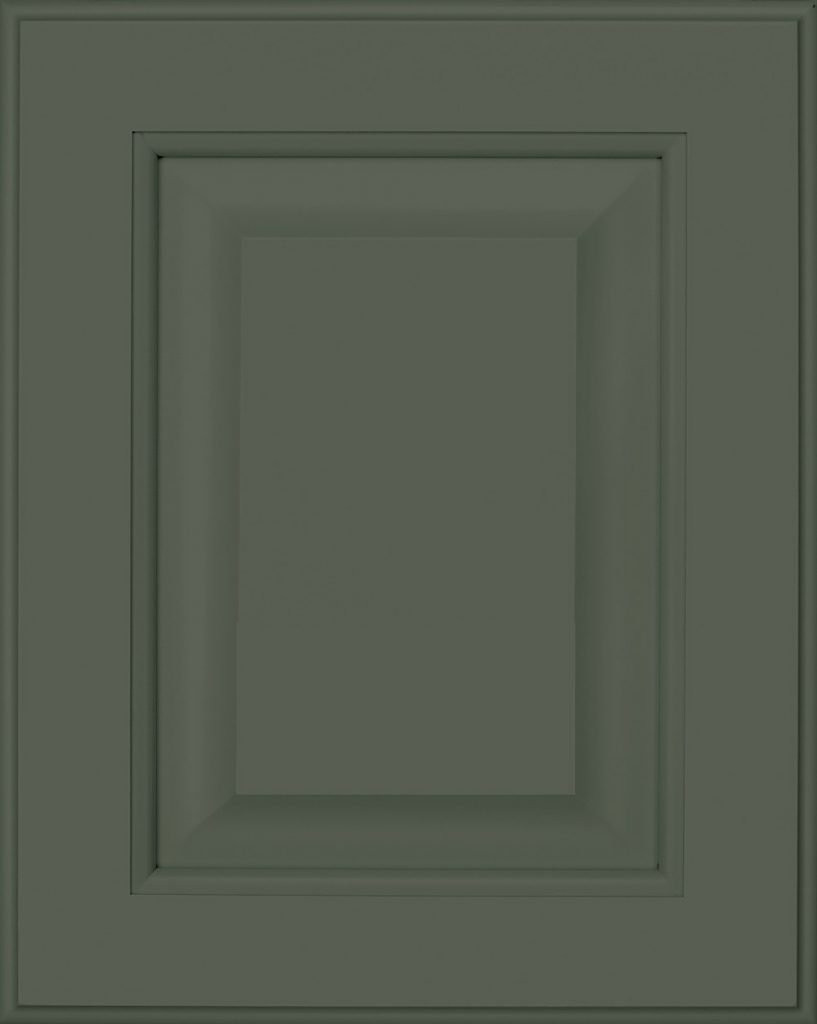

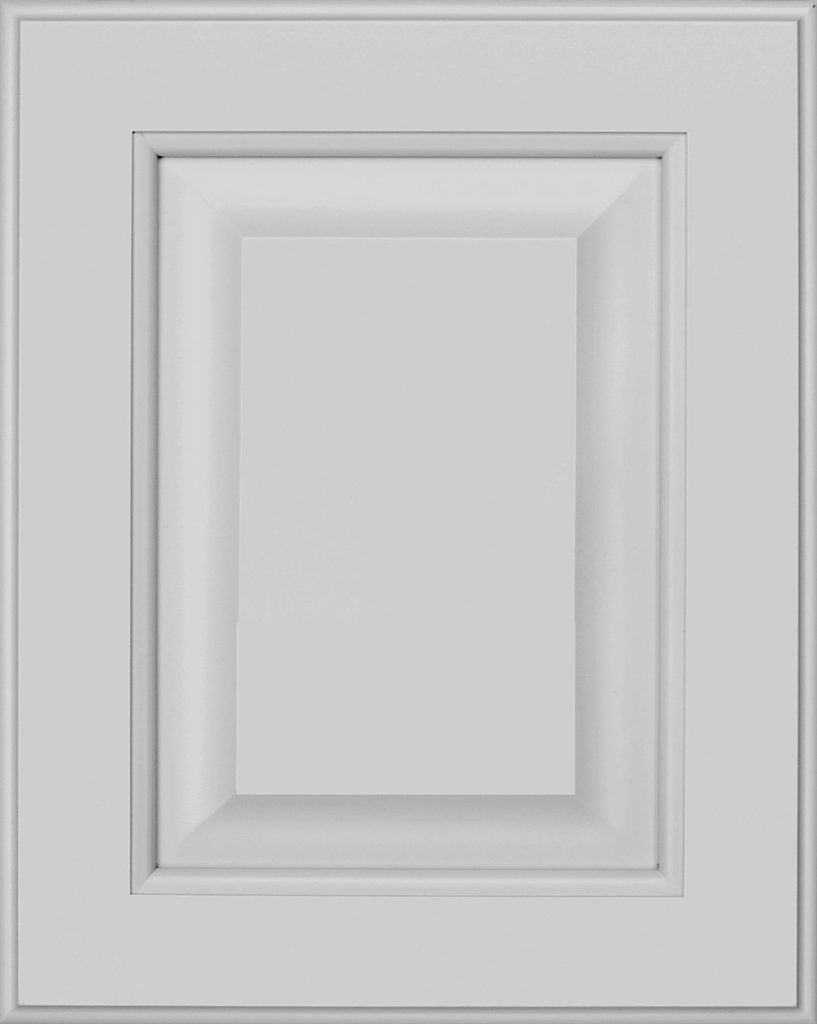

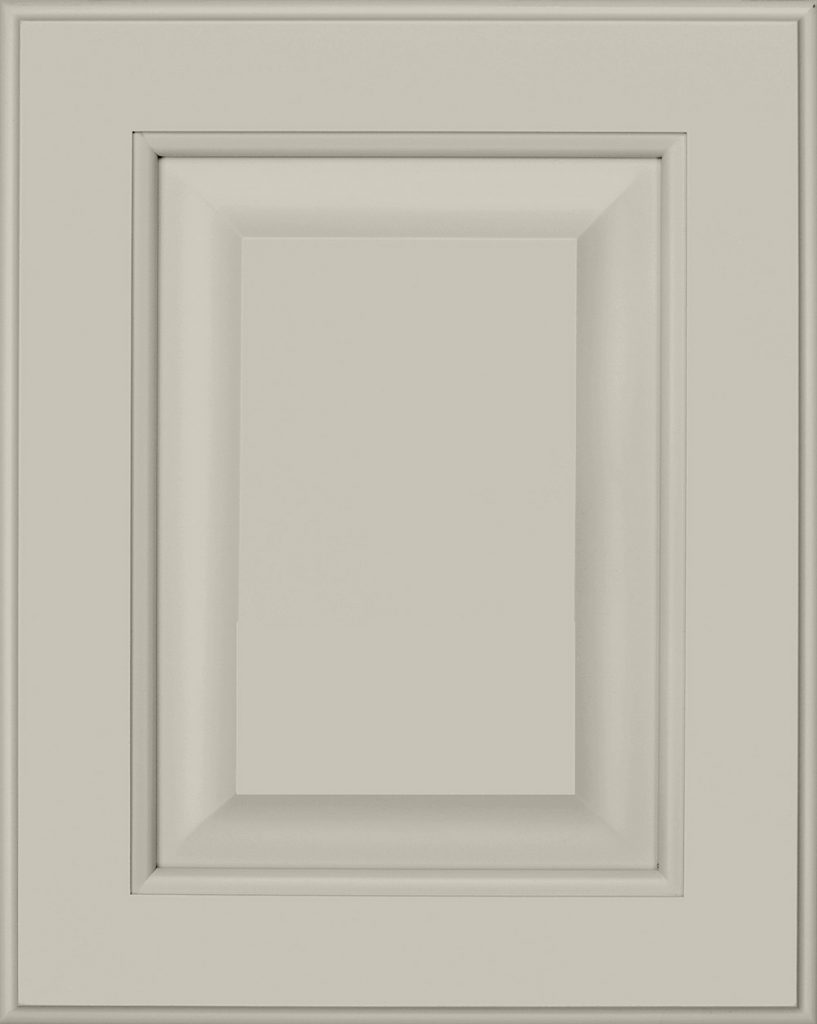

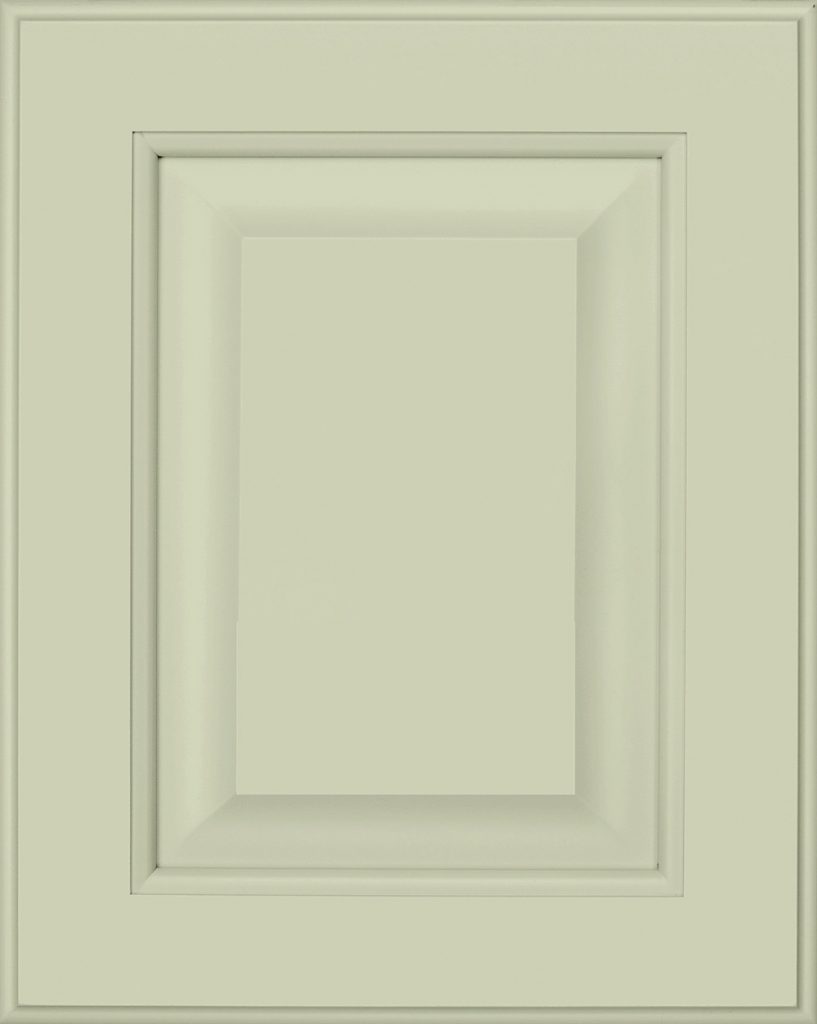

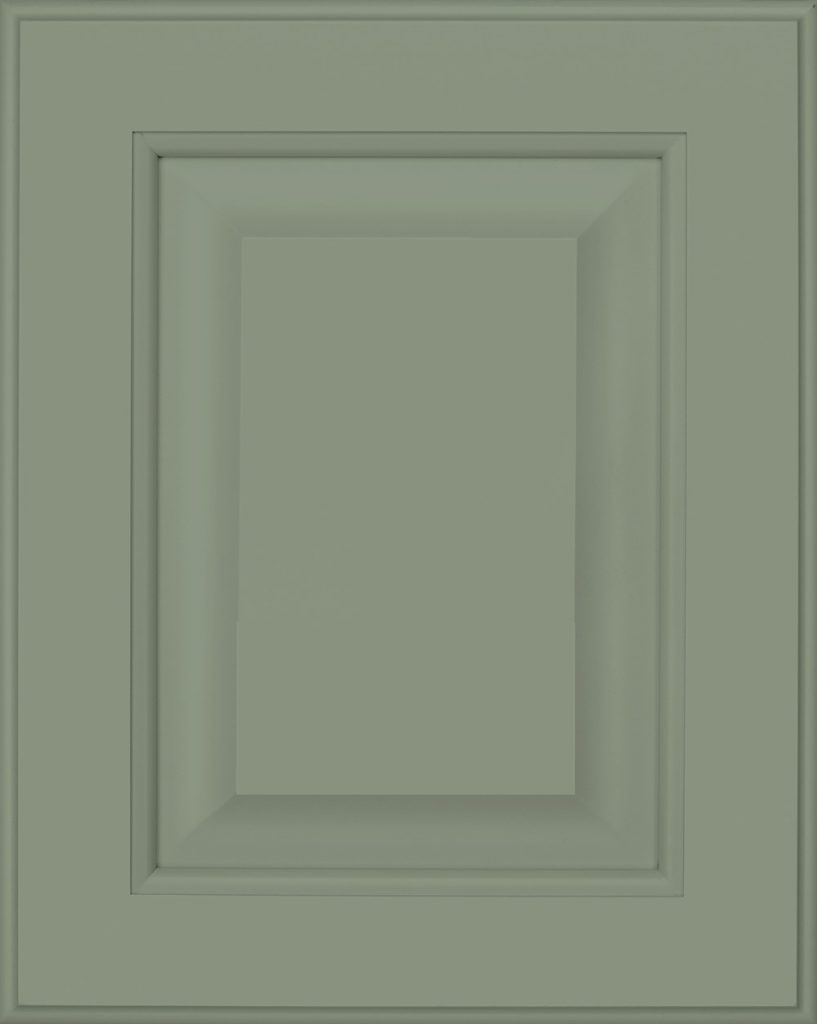

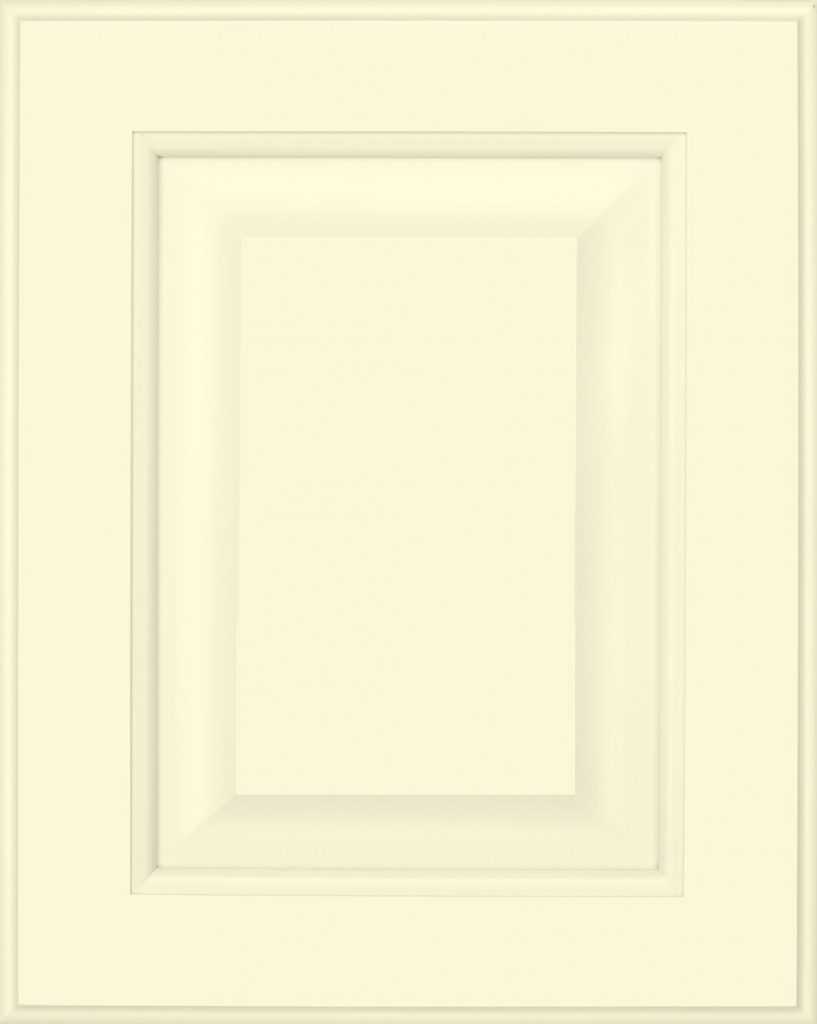

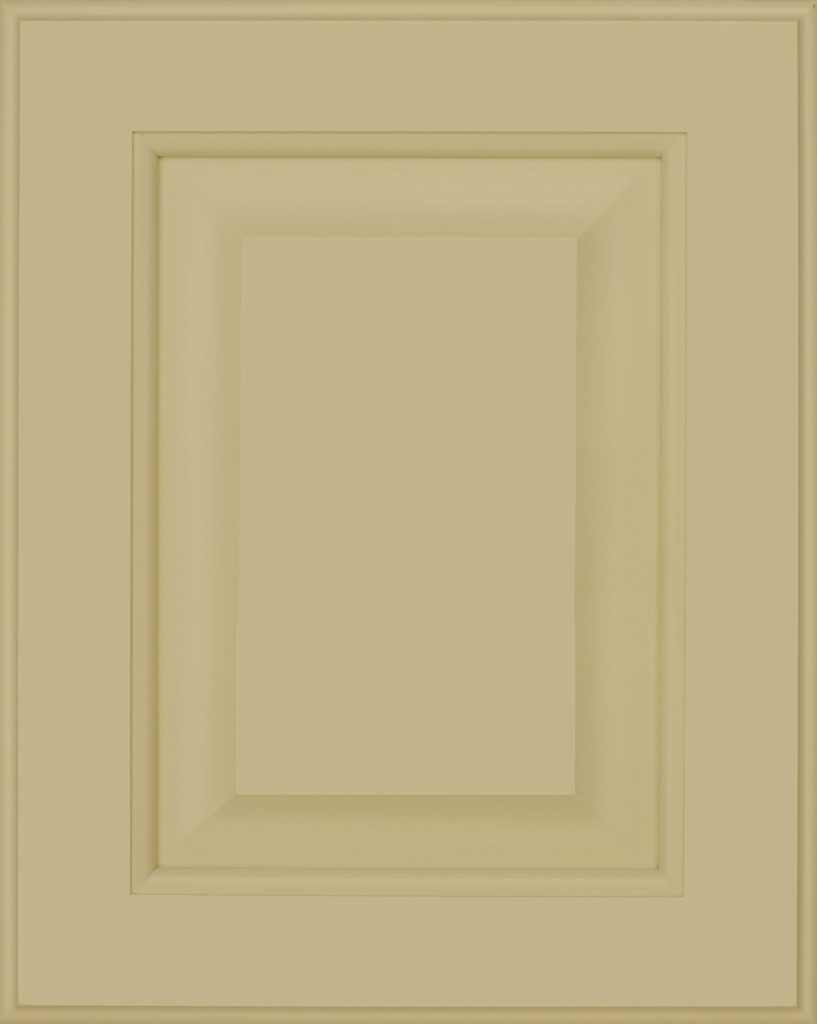

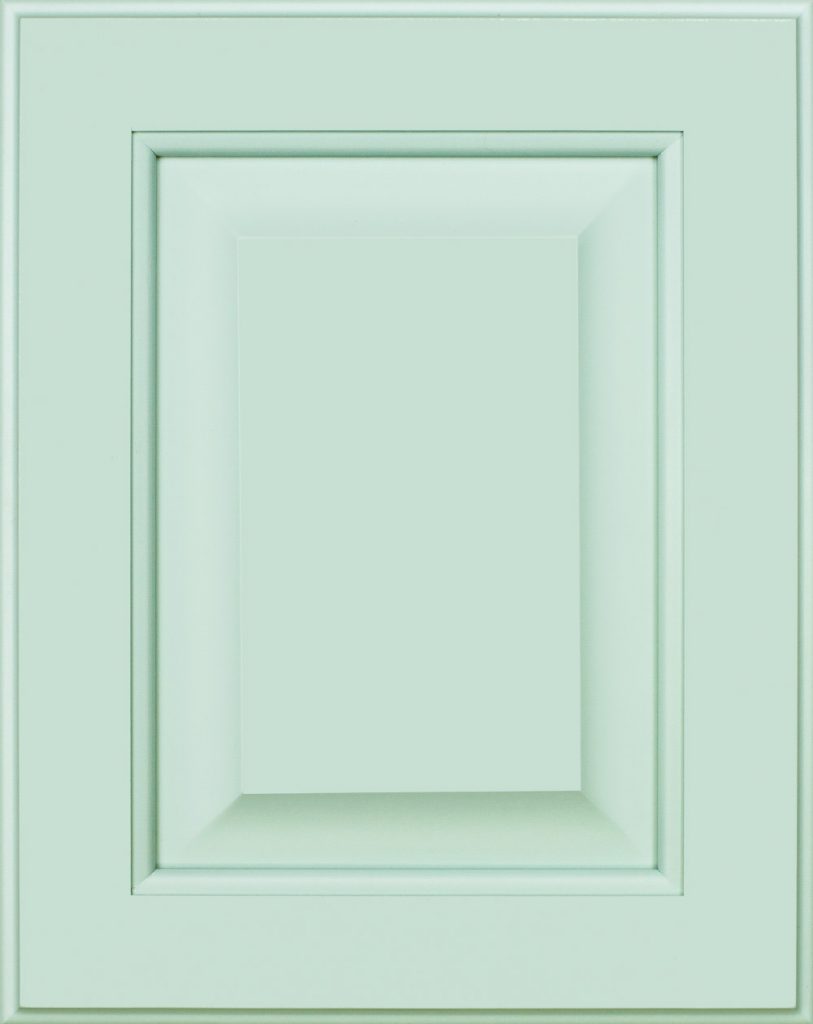

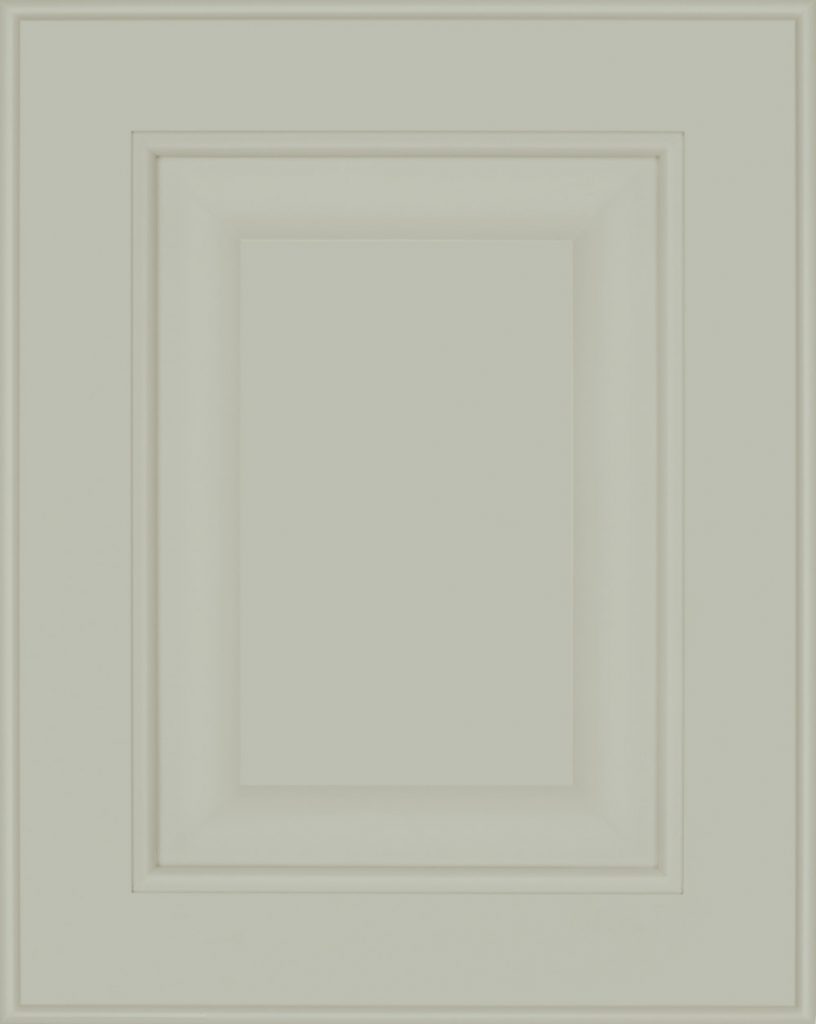

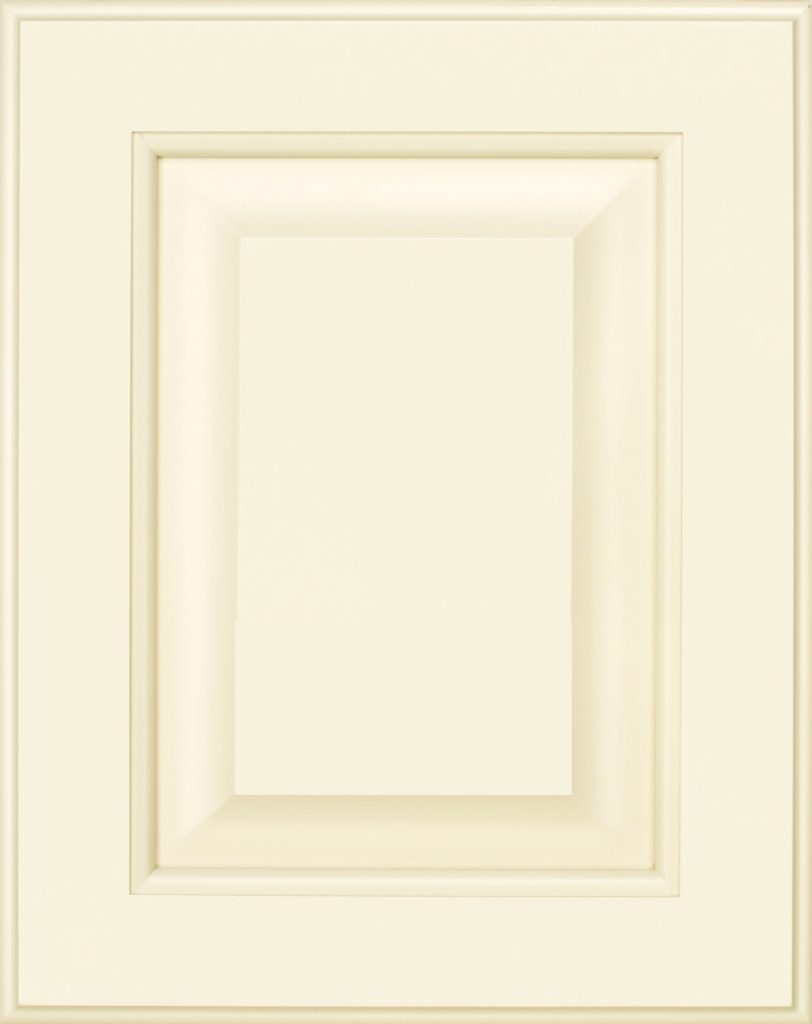

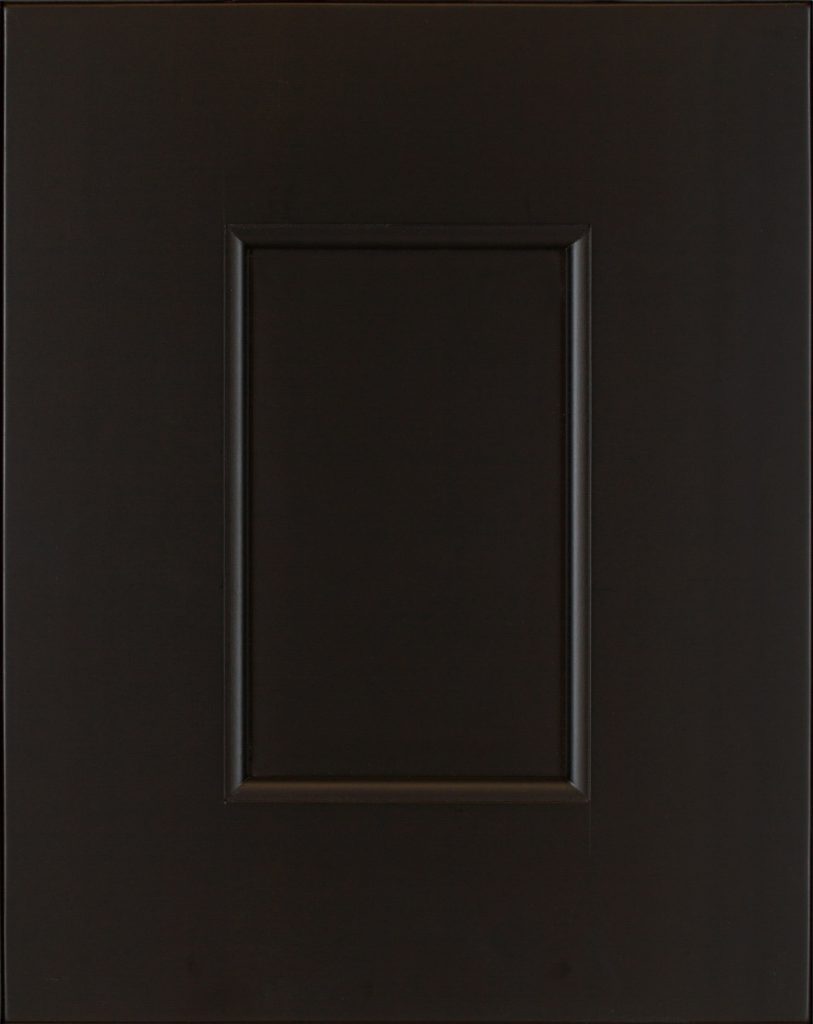

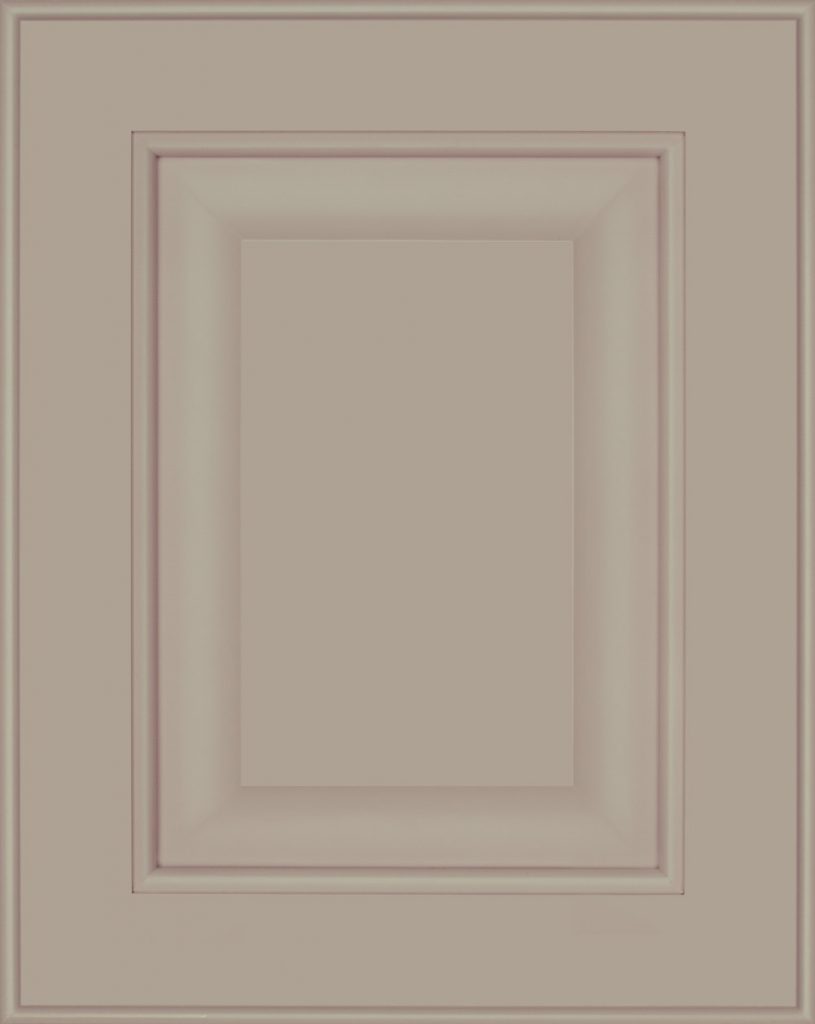

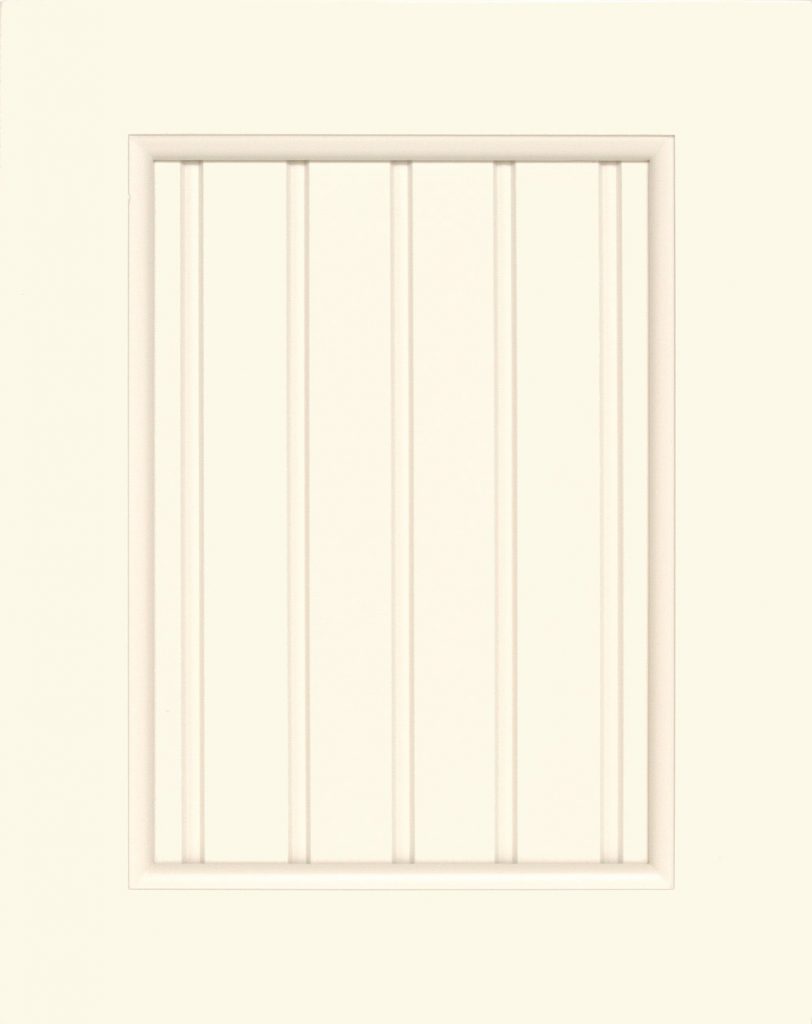

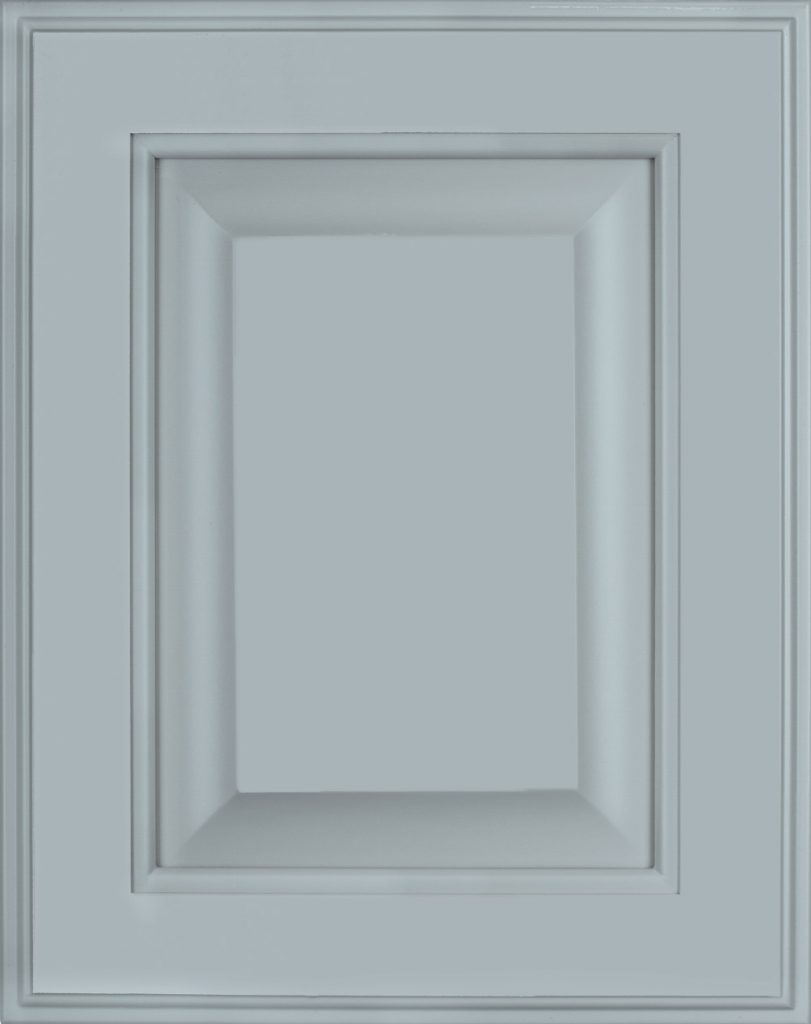

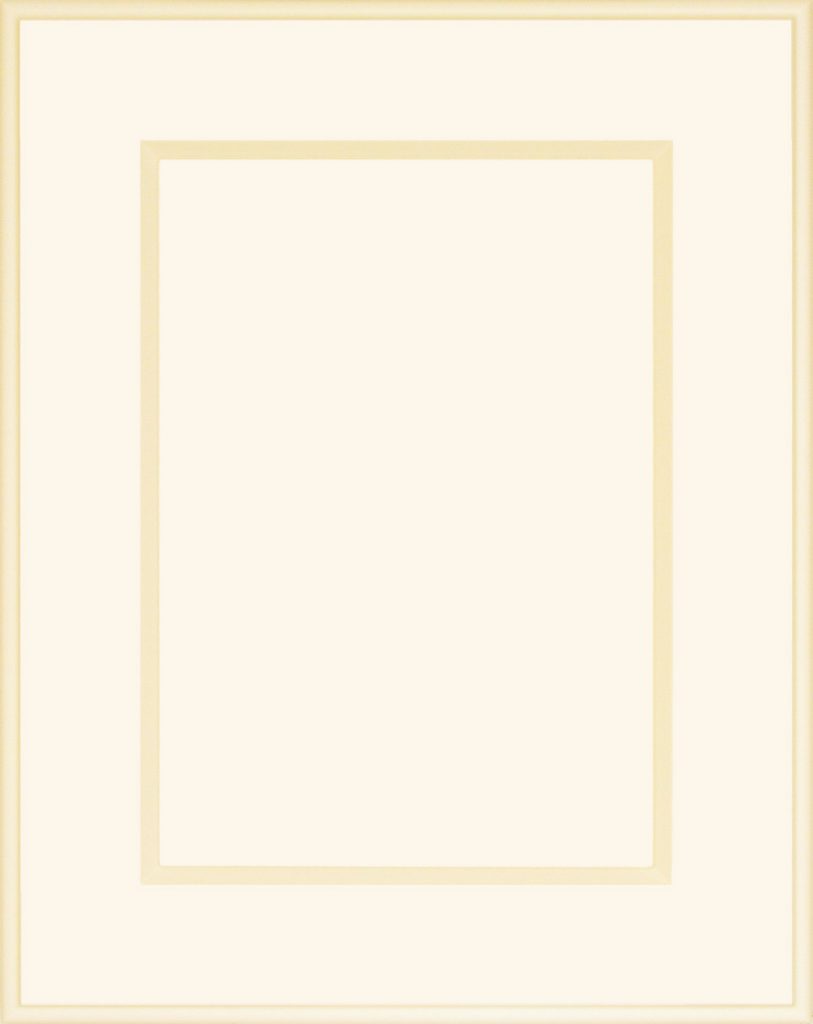

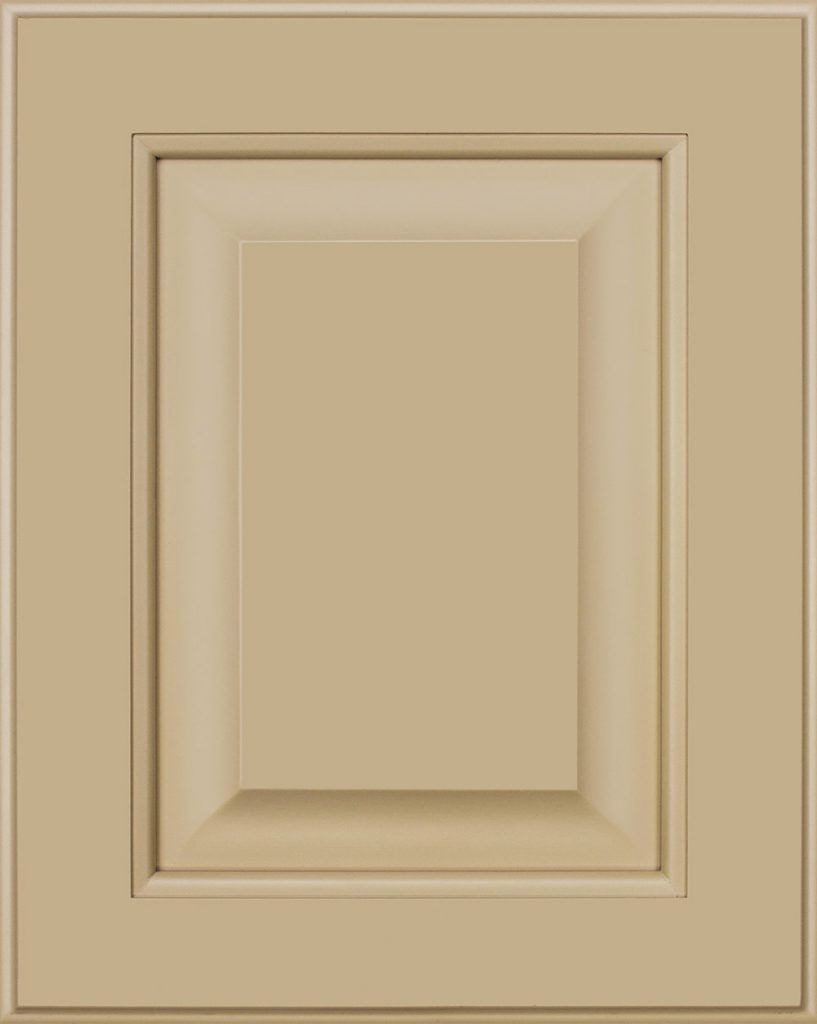

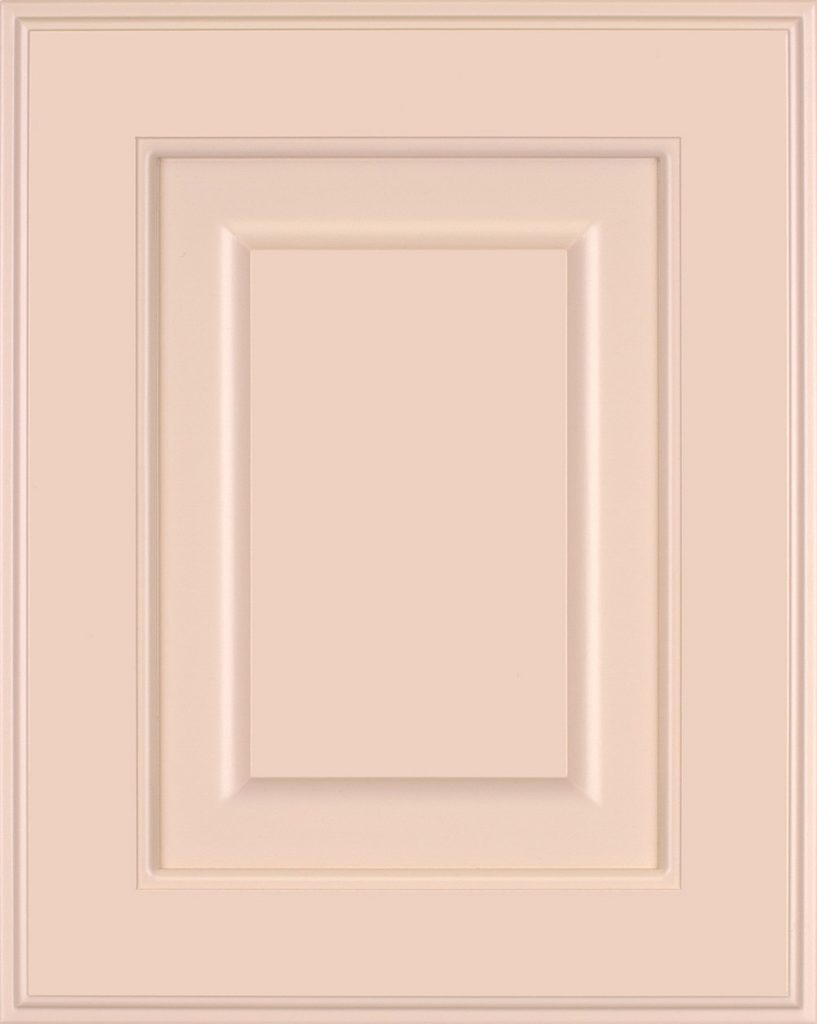

Click to see a larger sample

Click to see a larger sample

Click to see a larger sample

Click to see a larger sample

Click to see a larger sample

Click to see a larger sample

Click to see a larger sample

Click to see a larger sample

Click to see a larger sample

Click to see a larger sample

Explore the world of handcrafted furniture grade cabinetry that is tailored to fit you and your style.

Simply download a brochure or request information about a qualified dealer near you.

10/29/24 DOOR ASSEMBLY– Northwest area of cabinet assembly area where doors are assembled.

10/29/24 PURCHASING – Inventory area, looking north on hallway towards cage

10/29/24 PURCHASING – Inventory area, looking west by one of the building pillars full of cobwebs

36-page high-quality, high-resolution images of our standard and premium finishes, our paint finishes programs, door styles, construction, legs & posts, corbels, accessories, and embellishments and more. You can also order printed brochures, click here >

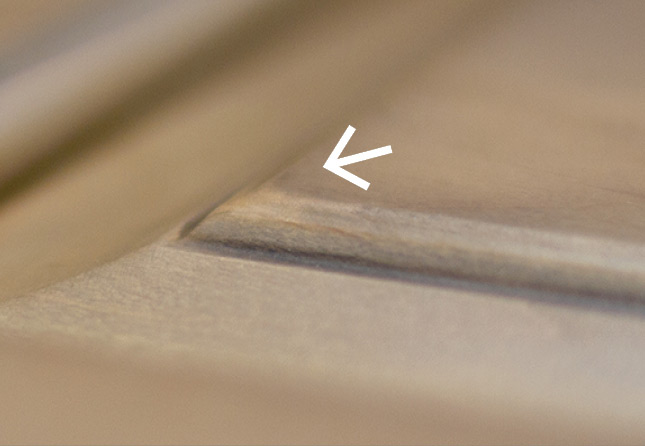

Tear outs along the edges of the door

Wear through, after stain is applied, before glaze/sheen

Tiny scratches in a tight pattern

Simulated saw marks on edges of the door

All corners are sanded before stain is applied to create a worn edge

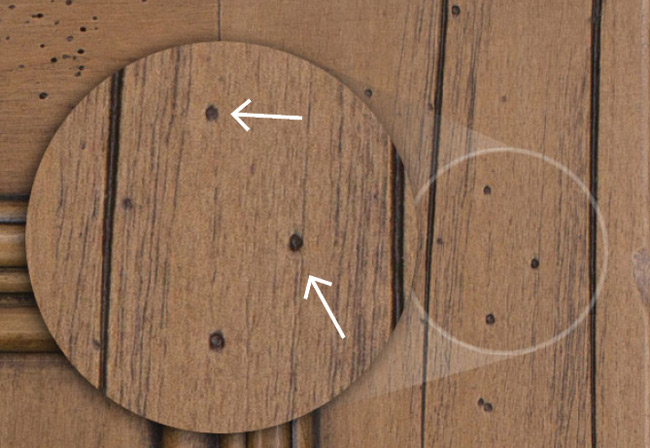

Random dents of various sizes, deeper, more widespread

Random placement of shallow dents

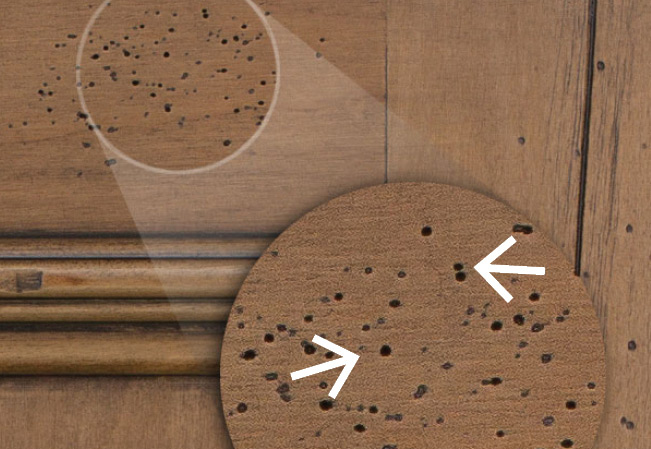

Very small lightly patterned holes in different areas of a door

Simulated cracks of varied lengths and sizes.

Random ice-pick markings in small clusters throughout the door